Thermoplastic PE Polyethylene hmoov txheej

PECOAT® PE Hmoov rau Polyethylene Powder Txheej

PECOAT® PE Polyethylene Powder yog ib thermoplastic hmoov txheej hloov nrog tsawg ntom polyethylene (LDPE) resin raws li cov khoom siv, tsim nrog ntau yam khoom siv ntxiv los muab kev ua haujlwm zoo. Nws muaj adhesion zoo heev, tiv thaiv corrosion, tshuaj lom neeg ruaj khov, hluav taws xob rwb thaiv tsev thiab kub tsis kam ntawm polyethylene nws tus kheej. Feem ntau, lawv tau dav siv los ua cov khoom siv hauv tsev thiab cov khoom siv hlau hlau. Qhov no yog vim hais tias lawv muab ib tug du thiab txaus nyiam nto txheej uas yog ib qho nyuaj txaus los tiv taus hnyav hnyav thiab tsim kua muag.

Peb tuaj yeem muab cov xim bespoke kom haum koj cov kev xav tau. RAL Xim Siv

PECOAT® thermoplastic polyethylene hmoov txheej yog tsim los rau toughness, ruaj thiab tiv thaiv corrosion, tsis muaj primer. Cov khoom siv yog ib puag ncig zoo, tsis muaj VOC, tsis muaj pa phem thaum siv. Nws cov txheej txheem thermoplastic ib txheej muab lub sij hawm ntev txuag ntawm kev saib xyuas, cov khoom siv thiab cov nqi khiav lag luam, thiab siv los ntawm ntau yam kev lag luam.

- Zoo tshuaj tiv thaiv

- Txhim kho qhov kub thiab txias

- Zoo heev mechanical resistance

- Hu rau zaub mov

- Ib puag ncig tus phooj ywg

- Du tag

- Zoo hardness

- Lub sij hawm ntev durability

- Superior corrosion kuj

- Muaj kev cuam tshuam thiab kev puas tsuaj

- UV stability

- Huab cua tsis kam (kev nyab xeeb, av noo, kub hloov pauv)

- Kev tiv thaiv ntawm galvanized substrate

- Ib puag ncig tus phooj ywg

- Zoo tiv taus kub

- Zoo UV stability, tsis muaj yellowing ntawm cov khoom dawb

- Flexible txheej, tsis muaj kev pheej hmoo ntawm kev tawg, chipping lossis flaking

- Ib puag ncig tus phooj ywg

- Kev tiv thaiv hlau zoo, suav nrog rau cov npoo ntse thiab welds

- Du tag

- Zoo hardness

- Cov tshuaj zoo heev thiab corrosion kuj

- Muaj kev cuam tshuam thiab kev puas tsuaj

- UV stability

- Kev tiv thaiv ntawm galvanized substrate

- Mos kov

- Ib puag ncig tus phooj ywg (tsis muaj VOC, halogen dawb, BPA dawb)

- Acid kuj

- Zoo heev adhesion thaum hloov tau

- Zoo heev rwb thaiv tsev

- Superior corrosion kuj, roj kuj

- Muaj kev cuam tshuam thiab kev puas tsuaj

- UV stability

- High adhesion thiab yooj

- Hluav taws xob rwb thaiv tsev

PECOAT® Cov Hluav Taws Xob Hluav Taws Xob Lub tog raj kheej Txheej yog tsim tshwj xeeb los pleev xim rau sab hauv ntawm cov dej thiab ua npuas dej tua hluav taws, nws yog siv los ntawm kev sib hloov hauv ob sab phlu rau cov hlau thooj voos kheej kheej kom muab cov txheej tiv thaiv zoo heev rau cov dej hauv ib puag ncig, nrog rau cov neeg ua npuas ncauj AFFF thiab tseem resistant mus txog 30% Antifreeze (ethylene glycol).

Fais fab cable conduit yog cov khoom sib xyaw ua los ntawm cov yeeb nkab steel ua lub hauv paus, coated nrog polyethylene hmoov txheej ntawm cov phab ntsa sab hauv thiab sab nrauv los ntawm cov txheej txheem tshwj xeeb thiab kho thaum kub kub. Vim nws qhov zoo tiv thaiv zoo li qub thiab tiv thaiv cov teeb liab sab nraud cuam tshuam, nws yog siv rau hauv kev tiv thaiv hluav taws xob hauv ntau qhov chaw.

PECOAT® PIB 506 polyethylene hmoov yog tsim rau txheej cable conduit (lub hwj chim conduit ). Nws yog ib qho hnyav-dawb, 100% khoom hmoov txheej tsim nrog kev ua haujlwm siab polyethylene ua lub hauv paus cob thiab ua ke nrog ntau yam tshwj xeeb resins. Cov khoom no muaj adhesion siab heev, zoo heev aging kuj, huab cua tsis kam, zoo flowability, thiab nta xws li hnyav-dawb, tsis-polluting, environmentally friendly, thiab lub zog txuag.

Nyeem ntxiv >>

25Kg / hnab

PECOAT® thermoplastic polyethylene hmoov txheej yog thawj zaug ntim rau hauv ib lub hnab yas kom tiv thaiv cov khoom kom tsis txhob muaj kab mob thiab ntub dej, nrog rau kom tsis txhob muaj hmoov av. Tom qab ntawd, ntim nrog lub hnab woven kom tswj tau lawv txoj kev ncaj ncees thiab tiv thaiv lub hnab yas sab hauv los ntawm kev puas tsuaj los ntawm cov khoom ntse. Thaum kawg palletize tag nrho cov hnab thiab qhwv nrog tuab tiv thaiv zaj duab xis kom ceev cov khoom thauj.

Tam sim no npaj rau kev xa khoom!

Cov txheej txheem sib txawv muaj qhov sib txawv ntawm cov cuab yeej txheej, xws li adhesion, ntws muaj peev xwm, kub endurance, thiab lwm yam, cov ntaub ntawv no yog lub hauv paus ntawm peb cov qauv tsim.

Txhawm rau kom ua tiav txoj hauv kev ua tiav ntawm cov qauv ntsuas, thiab ua lub luag haujlwm rau ob tog, ua siab zoo thov muab cov ntaub ntawv hauv qab no. Ua tsaug ntau rau koj txoj kev kho mob hnyav thiab kev koom tes.

- Yam khoom koj lub tsho? Nws yog qhov zoo dua los xa peb daim duab.

- Dab tsi yog cov khoom siv substrate, galvanized lossis non-galvanized?

- Rau cov qauv kuaj, 1-25kg / xim, xa los ntawm huab cua.

- Rau kev txiav txim, 1000kg / xim, xa los ntawm hiav txwv.

- Kev tshem tawm cov tshuab: Siv cov cuab yeej xws li cov ntawv xuab zeb, txhuam hlau, lossis cov log abrasive los txhuam lossis zom cov txheej txheem.

- Cua sov: Siv cov cua sov rau txheej uas siv rab phom cua sov lossis lwm yam khoom siv cua sov los pab kom nws tshem tawm.

- Chemical strippers: Siv cov tshuaj tsim nyog strippers tshwj xeeb tsim rau cov hmoov txheej, tab sis ua raws li kev ceev faj thaum siv lawv. Qhov no yog ib tug muaj zog acid los yog lub hauv paus muaj zog.

- Sandblasting: Txoj kev no tuaj yeem tshem tawm cov txheej txheem, tab sis xav tau lub tshuab sandblasting.

- Scraping: Siv cov cuab yeej ntse los ua tib zoo khawb tawm cov txheej.

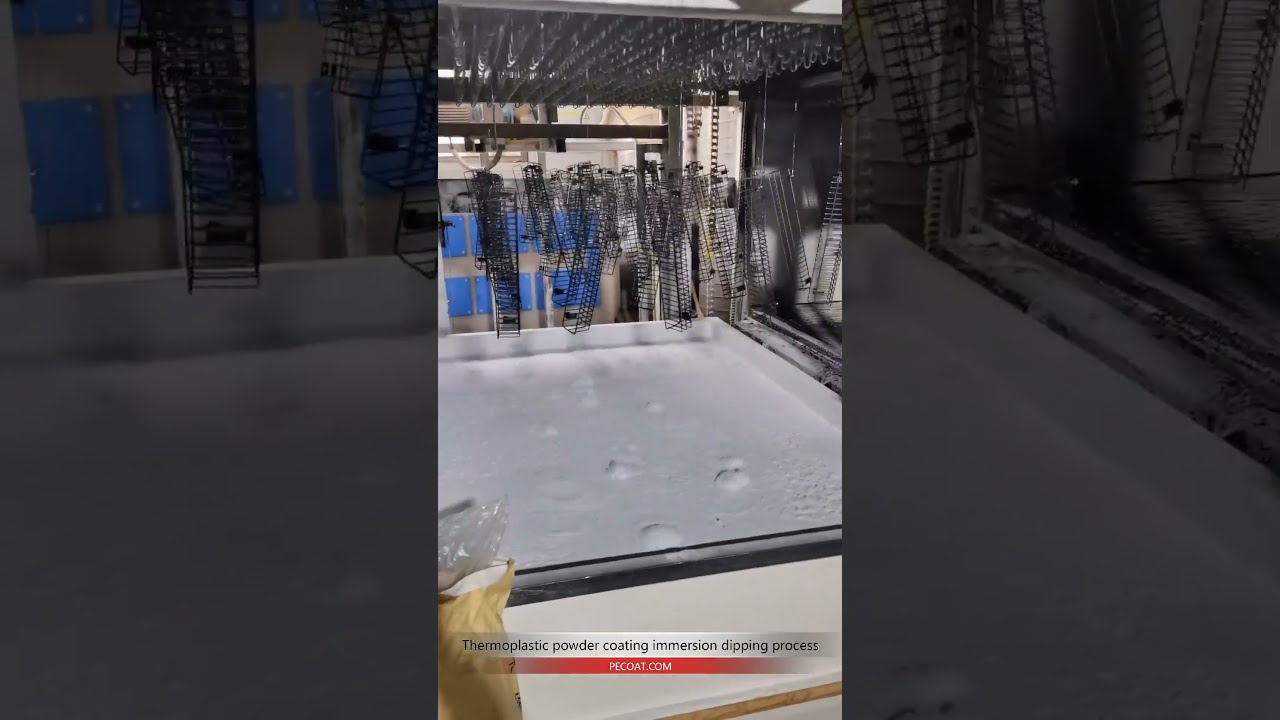

Lub preheated workpiece yog kiag li immersed rau hauv fluidized txaj. Cov hmoov melts ntawm kev sib cuag nrog lub workpiece thiab lub workpiece yog ces nqa tawm ntawm lub txaj fluidized. Tom qab ntawd lub workpiece yog txias kom tawm hauv cov txheej txheem zoo.

Lub preheated workpiece yog kiag li immersed rau hauv fluidized txaj. Cov hmoov melts ntawm kev sib cuag nrog lub workpiece thiab lub workpiece yog ces nqa tawm ntawm lub txaj fluidized. Tom qab ntawd lub workpiece yog txias kom tawm hauv cov txheej txheem zoo.

- Kev kho ua ntej: Roj thiab xeb tshem tawm los ntawm cov txheej txheem tshuaj los yog sandblasting.

- Workpiece Preheat: 250-320 ℃ [hloov raws li lub workpiece].

- Fluidized txaj Dip: 4-8 vib nas this [kho raws li lub workpiece].

- Tom qab cua sov (yeem): 180-250 ℃, 5 feeb [Txoj kev tau txais qhov chaw zoo dua].

- Txias: Cua txias los yog txias txias.

Peb cov electrostatic series ntawm cryogenically-hauv av hmoov yog zoo txaus kom tau electrostatically them thiab txau mus rau grounded hlau workpieces. Cov hlau workpieces ces muab tso rau hauv qhov cub muaj thiab rhuab kom txog thaum cov hmoov melts. Cov khoom tom qab ntawd txias kom tawm hauv cov txheej txheem zoo.

Peb cov electrostatic series ntawm cryogenically-hauv av hmoov yog zoo txaus kom tau electrostatically them thiab txau mus rau grounded hlau workpieces. Cov hlau workpieces ces muab tso rau hauv qhov cub muaj thiab rhuab kom txog thaum cov hmoov melts. Cov khoom tom qab ntawd txias kom tawm hauv cov txheej txheem zoo.  Lub workpiece yuav tsum tau coated yuav tsum preheated ntawm qhov tsim nyog kub, depending ntawm nws cov khoom, thickness, thiab tshav kub muaj peev xwm. Uncharged hmoov yog tshuab rau cov hlau kub, qhov chaw nws melts thiab tsim ib txheej. Tom qab ntawd cov khoom raug tso cai kom txias kom tawm hauv cov txheej txheem zoo.

Lub workpiece yuav tsum tau coated yuav tsum preheated ntawm qhov tsim nyog kub, depending ntawm nws cov khoom, thickness, thiab tshav kub muaj peev xwm. Uncharged hmoov yog tshuab rau cov hlau kub, qhov chaw nws melts thiab tsim ib txheej. Tom qab ntawd cov khoom raug tso cai kom txias kom tawm hauv cov txheej txheem zoo.  Cov khoom uas yuav tsum tau txheej, feem ntau yog lub raj mis, yeeb nkab lossis lub tog raj kheej, yog cua sov mus txog qhov kub thiab txias. Fluidized txaj hmoov yog ces txhaj rau hauv cov khoom. Cov khoom yog tam sim ntawd spun thiab tumbled kom muab ib tug ua tiav thiab zoo ib yam txheej nyob rau hauv lub raj mis. Cov hmoov uas tsis tau siv yog ces muab tawm ntawm qhov khoom.

Cov khoom uas yuav tsum tau txheej, feem ntau yog lub raj mis, yeeb nkab lossis lub tog raj kheej, yog cua sov mus txog qhov kub thiab txias. Fluidized txaj hmoov yog ces txhaj rau hauv cov khoom. Cov khoom yog tam sim ntawd spun thiab tumbled kom muab ib tug ua tiav thiab zoo ib yam txheej nyob rau hauv lub raj mis. Cov hmoov uas tsis tau siv yog ces muab tawm ntawm qhov khoom.  Cov hmoov thermoplastic yog dispersed los ntawm rab phom nozzle thiab tshuab hauv cov nplaim hluav taws tsim nyob ib ncig ntawm lub nozzle, cov hmoov melts ntawm kev thauj mus los ntawm rab phom mus rau qhov chaw ua hauj lwm thiab tam sim ntawd hloov cov txheej txheej thaum muaj kev sib cuag nrog lub workpiece.

Cov hmoov thermoplastic yog dispersed los ntawm rab phom nozzle thiab tshuab hauv cov nplaim hluav taws tsim nyob ib ncig ntawm lub nozzle, cov hmoov melts ntawm kev thauj mus los ntawm rab phom mus rau qhov chaw ua hauj lwm thiab tam sim ntawd hloov cov txheej txheej thaum muaj kev sib cuag nrog lub workpiece.

| PE hmoov txheej | PVC Hmoov Txheej | |

|---|---|---|

| Curing Kub | 180-220 ℃ | 230 ° C-250 ° C (ntau zog siv) |

| Ib puag ncig zoo | Yog | Tsis muaj (teeb meem roj HCL emission thaum siv) |

| Txheej Thickness | 200-2000μm (ntau yam tuab, tswj tau yooj yim) | 800-1000μm (nqi ntau thickness, ib txwm nyias txheej) |

| Hmoov noj (ntawm tib lub thickness) | tsawg | ntau |

| Deg | Smooth | Ib me ntsis ntxhib, tsis heev smooth |

| Adhesion Muaj peev xwm | zoo heev | Tsis muaj, tshwj xeeb primer yuav tsum tau |

| nqe | High | Pheej Yig |

| Kev xa khoom hauv Sijhawm |

|

| Xim Sib Xws |

|

| Kev Pabcuam Tshaj Haujlwm |

|

| Kev sib raug zoo |

|

| Kev thauj mus los nyab xeeb |

|

|

NIAM TXIV

|

5.0

|