Plastic Coating For Metal

Plastic coating for metal process ndeyekuisa danda repurasitiki pamusoro pezvikamu zvesimbi, izvo zvinovatendera kuchengetedza hunhu hwesimbi hwepakutanga vachipawo zvimwe zvimiro zvepurasitiki, senge corrosion resistance, kupfeka kuramba, magetsi ekudzivirira, uye kuzvimiririra. -kuzora. Iyi nzira yakakosha zvikuru mukuwedzera huwandu hwekushandisa kwezvigadzirwa uye kuwedzera kukosha kwazvo kwehupfumi.

Nzira dzekugadzira purasitiki yesimbi

Kune nzira dzakawanda dzekuputira epurasitiki, kusanganisira kupfapfaidza murazvo, fluidized bed kupfapfaidza, poda electrostatic spraying, inopisa kunyunguduka coating, uye kuturika coating. Kune zvakare akawanda marudzi emapurasitiki anogona kushandiswa kupfekedza, ane PVC, PE, uye PA ndiyo inonyanya kushandiswa. Purasitiki inoshandiswa pakupfekedza inofanira kunge iri muhupfu, ine fineness ye80-120 mesh.

Mushure mekuputira, zviri nani kukurumidza kutonhora workpiece nekuinyudza mumvura inotonhora. Kukurumidza kutonhora kunogona kuderedza crystallinity yekuputira epurasitiki, kuwedzera mvura yemukati, kunatsiridza kuoma uye kupenya kwepamusoro kwejasi, kuwedzera kunamatira, uye kukunda kuvhara kwekuvhara kunokonzerwa nekushushikana kwemukati.

Kuti uvandudze kusungirirwa pakati pekuputira uye nheyo yesimbi, pamusoro pebasa rekushanda rinofanira kunge risina guruva uye rakaoma, risina ngura uye mafuta asati avhara. Muzviitiko zvakawanda, workpiece inoda kurapwa pamusoro. Nzira dzekurapa dzinosanganisira sandblasting, makemikari kurapwa, uye dzimwe nzira dzemuchina. Pakati pavo, sandblasting ine mhedzisiro iri nani sezvo inoomesa pamusoro peiyo workpiece, ichiwedzera nzvimbo yepamusoro uye kugadzira zvikorekedzo, nokudaro kuvandudza kunamatira. Mushure mekuputika kwejecha, iyo workpiece yepamusoro inofanira kuputirwa nemhepo yakachena yakamanikidzwa kubvisa guruva, uye plastiki inofanira kuvharwa mukati meawa matanhatu, kana zvisina kudaro, nzvimbo yacho ichave oxidize, inokanganisa kusungirirwa kwejasi.

Chazvakanakira

Kunanga kwakananga nepurasitiki yehupfu kune zvinotevera zvakanakira:

- Inogona kushandiswa neresin inongowanikwa muhupfu.

- Iyo yakakora coating inogona kuwanikwa mune imwe application.

- Zvigadzirwa zvine maumbirwo akaomarara kana mipendero yakapinza zvinogona kupfekedzwa zvakanaka.

- Mapurasitiki mazhinji ehupfu ane kugadzikana kwekuchengetedza kwakanaka.

- Hapana zvinonyungudutsa zvinodikanwa, zvichiita kuti maitiro ekugadzirira zvinhu ave nyore. Nekudaro, kune zvakare zvimwe zvipingamupinyi kana zvipingamupinyi kune poda coating. Semuenzaniso, kana workpiece inoda kugadzirirwa, hukuru hwayo huchave hushoma. Nokuti nzira yekuputira inotora nguva, kune yakakura-saizi workpieces, nepo kupfapfaidza kusati kwapera, dzimwe nzvimbo dzakatotonhodzwa pasi petembiricha inodiwa. Munguva yepurasitiki yekuputira poda, kurasikirwa kwehupfu kunogona kunge kwakakwira kusvika 60%, saka inofanirwa kuunganidzwa uye kushandiswa zvakare kuti isangane nehupfumi zvinodiwa.

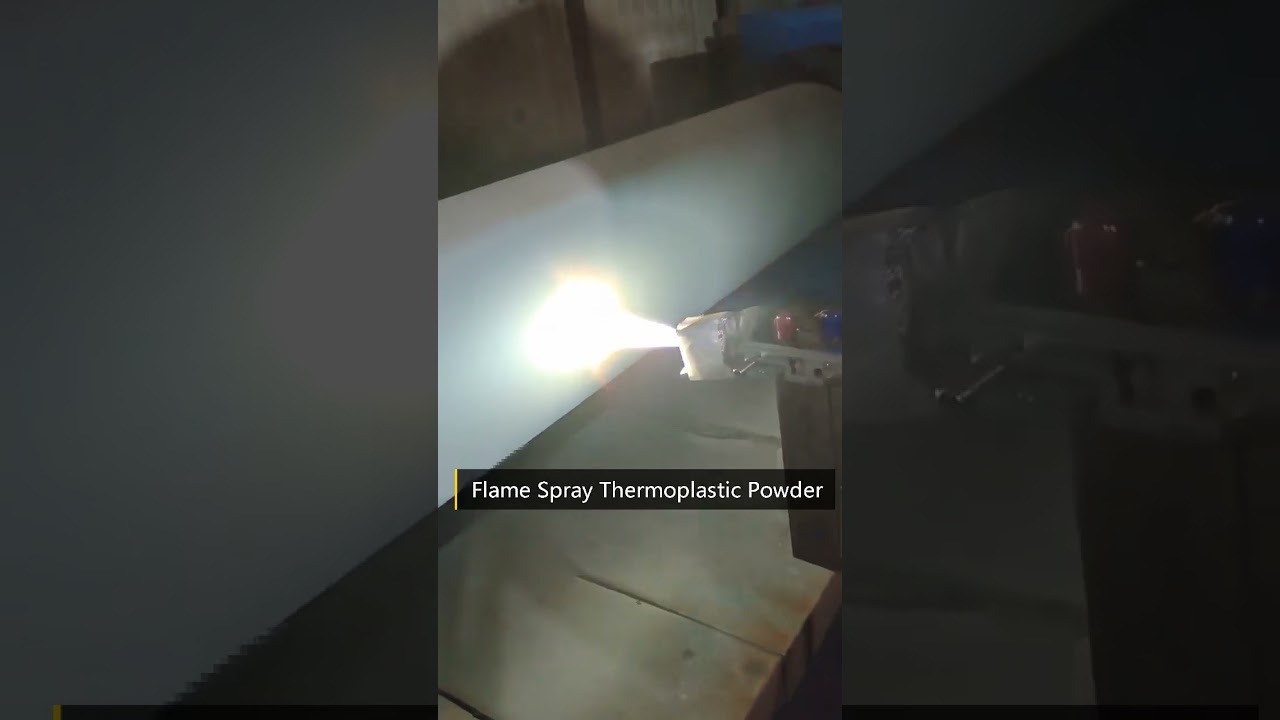

Flame Spraying

Flame spraying plastic coating for metal process inosanganisira kunyunguduka kana kunyungudusa purasitiki yakapfurwa kana kunamira ine murazvo unobuda mupfuti yekupfapfaidza, wozomwaya purasitiki yakanyungudutswa pamusoro pechinhu kuti chigadzire purasitiki. Ukobvu hwekuputira kazhinji huri pakati pe 0.1 uye 0.7 mm. Paunenge uchishandisa purasitiki yehupfu yekupfapfaidza murazvo, iyo workpiece inofanira kunge isati yapisa. Preheating inogona kuitwa muovheni, uye tembiricha yekupisa inosiyana depending parudzi rwepurasitiki iri kupfapfaidzwa.

Tembiricha yemurazvo panguva yekupfapfaidza inofanirwa kudzorwa zvakanyanya, sezvo tembiricha yakanyanya kupisa kana kukuvadza plastiki, nepo tembiricha yakadzikira inogona kukanganisa kunamatira. Kazhinji, tembiricha yakakwira kana uchipfapfaidza chikamu chekutanga chepurasitiki, chinogona kuvandudza kunamatira pakati pesimbi nepurasitiki. Sezvo zvikamu zvinotevera zvakapfapfaidzwa, tembiricha inogona kudzikiswa zvishoma. Nharaunda pakati pepfuti yekupfapfaidza uye workpiece inofanira kuva pakati pe100 ne200 cm. Kune flat workpieces, workpiece inofanira kuiswa yakatwasuka uye pfuti yekupfapfaidza inofanira kuendeswa mberi neshure; ye cylindrical kana yemukati bore workpieces, inofanira kuiswa palathe yekupoterera kupfapfaidza. Kumhanya kwemutsara weiyo inotenderera workpiece inofanira kuva pakati pe20 ne60 m/min. Mushure mokunge hupamhi hunodiwa hwekuputira hwave huchiitwa, kupfapfaidza kunofanira kumira uye workpiece inofanira kuramba ichitenderera kusvikira ipurasitiki yakanyungudutswa yaoma, uye inofanira kukurumidza kutonhora.

Kunyangwe kupfapfaidza murazvo kune kushomeka kwekugadzira uye kunosanganisira kushandiswa kwemagasi anogumbura, ichiri nzira yakakosha yekugadzira muindasitiri nekuda kwekudyara kwayo kwemidziyo yepasi uye kushanda zvakanaka mukunamira mukati mematangi, midziyo, uye makuru workpieces zvichienzaniswa nedzimwe nzira. .

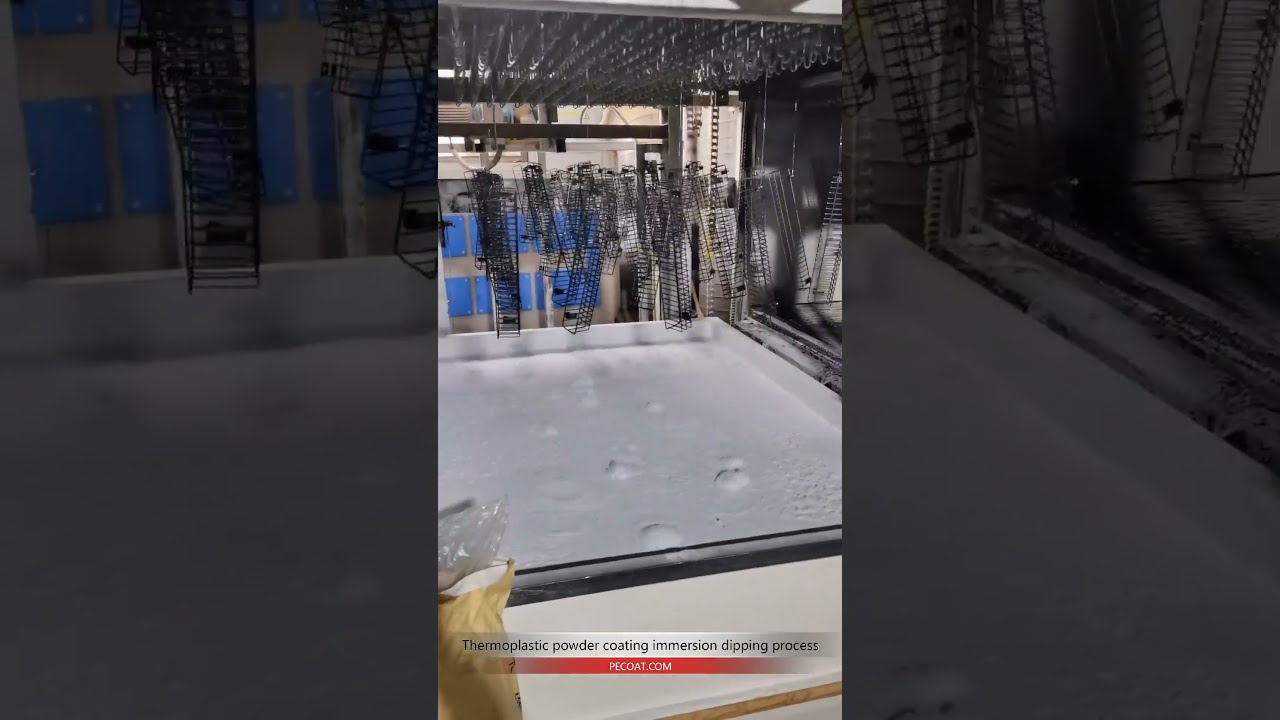

Fluidized-mubhedha Dip Plastic Coating

Nheyo yekushanda ye-fluidized bed dip plastic coating yesimbi ndeyotevera: plastiki yekuputira poda inoiswa mumudziyo wecylindrical ine porous partition kumusoro iyo inobvumira mhepo chete kupfuura, kwete poda. Kana mweya wakatsikirirwa ukapinda kubva pasi pegaba, unofuridzira poda kumusoro uye woimisa mugaba. Kana iyo preheated workpiece yakanyudzwa mairi, resin poda inonyunguduka uye inonamatira kune workpiece, ichigadzira jasi.

Ukobvu hwejasi hunowanikwa mumubhedha wakanyungudika depends pane tembiricha, chaiyo kupisa huwandu, pamusoro coefficient, nguva yekupfapfaidza, uye mhando yepurasitiki inoshandiswa kana workpiece ichipinda mukamuri yakanyungudika. Nekudaro, chete tembiricha uye nguva yekupfapfaidza yeiyo workpiece inogona kudzorwa mukuita, uye ivo vanofanirwa kutariswa nekuyedza mukugadzira.

Panguva yekunyura, inodiwa kuti hupfu hwepurasitiki huyerere zvakanaka uye zvakaenzana, pasina kuungana, kuyerera kwevortex, kana kupararira kwakanyanya kwezvidimbu zvepurasitiki. Matanho anowirirana anofanira kutorwa kuti asangane nezvinodiwa izvi. Kuwedzera mudziyo unosimudzira unogona kuderedza agglomeration uye kuyerera kwevortex, nepo kuwedzera hushoma hwetalcum hupfu kune hupfu hwepurasitiki hunobatsira pakuyerera, asi hunogona kukanganisa kunaka kwekuputira. Kudzivirira kupararira kwezvikamu zvepurasitiki, chiyero chekuyerera kwemhepo uye kufanana kwezvikamu zveupfu zvepurasitiki zvinofanira kunyatsodzorwa. Zvisinei, kumwe kupararira hakudzivisiki, saka chigadziro chekudzorera chinofanira kuiswa muchikamu chepamusoro chemubhedha wemvura.

Zvakanakira zvemvura yakanyungudutswa yemubhedha dip epurasitiki coating ndiko kugona kupfekedza maumbirwo-akaomesesa ebasa, yakakwira coating mhando, kuwana yakakora yekupfeka mune imwe application, kushoma resin kurasikirwa, uye yakachena nharaunda yekushanda. Izvo zvisingabatsiri ndiko kuoma kwekugadzirisa makuru workpieces.

Electrostatic spraying plastic coating yesimbi

Mukupfapfaidza kwemagetsi, resin epurasitiki yekuputira poda inomisikidzwa pamusoro peiyo workpiece nemagetsi emagetsi simba, pane kunyungudika kana kunyungudika. Nheyo yacho ndeyekushandisa iyo electrostatic munda inoumbwa ne-high-voltage electrostatic jenareta kuchaja resin poda yakapfapfaidzwa kubva mupfuti yekupfapfaidza ine static magetsi, uye yakadzika workpiece inova yakakwirira-voltage positive electrode. Nekuda kweizvozvo, chidimbu cheunifomu yepurasitiki poda inokurumidza kuisa pamusoro peiyo workpiece. Pamberi pekuchaja kwapera, hupfu hwehupfu hunonamatira zvakasimba. Mushure mekupisa uye kutonhora, yunifomu yepurasitiki yekuputira inogona kuwanikwa.

Powder electrostatic spraying yakagadzirwa pakati pemakore ekuma1960 uye iri nyore kuita otomatiki. Kana iyo yekuputira isingade kuve gobvu, electrostatic spraying haidi preheating yeworkpiece, saka inogona kushandiswa kune kupisa-sensitive zvinhu kana workpieces zvisina kukodzera kupisa. Izvo zvakare hazvidi hombe yekuchengetera mudziyo, iyo yakakosha mukupfapfaidza mubhedha. Iyo poda inodarika iyo workpiece inokwezvwa kuseri kweiyo workpiece, saka huwandu hwe overspray hushoma pane dzimwe nzira dzekupfapfaidza, uye iyo workpiece yese inogona kuvharwa nekupfapfaidza kune rumwe rutivi. Nekudaro, maworkpiece mahombe achiri kuda kupfapfaidzwa kubva kumativi ese.

Zvishandiso zvine zvidimbu zvakasiyana-siyana zvinogona kuunza matambudziko pakupisa kunotevera. Kana mutsauko wemuchinjiko wakakurisa, chikamu chakakora chejasi chinogona kusasvika pakunyungudika, nepo chikamu chakaonda chingave chanyungudika kana kuderedzwa. Muchiitiko ichi, kugadzikana kwekupisa kwe resin kunokosha.

Zvikamu zvine makona emukati akashambidzika uye maburi akadzika hazvifukidzwe nyore nekupfapfaidza kwemagetsi nekuti nzvimbo idzi dzine electrostatic shielding uye r.epel poda, ichidzivisa kuvhara kubva pakupinda mumakona kana maburi kunze kwekunge pfuti yespray inogona kuiswa mukati mavo. Pamusoro pezvo, kupfapfaidza kwemagetsi kunoda zvimedu zvakapfava nekuti zvimedu zvihombe zvinowanzo bvisa kubva pachigadzirwa, uye zvimedu zvakatsetseka kupfuura 150 mesh zvinonyanya kushanda mukuita kwemagetsi.

Hot melt coating nzira

Nheyo yekushanda yeiyo inopisa melt coating method ndeyekupfapfaidza purasitiki yekuputira poda pane preheated workpiece uchishandisa pfuti yekupuruzira. Iyo plastiki inonyunguduka nekushandisa kupisa kweiyo workpiece, uye mushure mekutonhora, jira repurasitiki rinogona kuiswa kune workpiece. Kana zvichidikanwa, mushure mekupisa kurapwa kunodiwawo.

Iyo kiyi yekudzora inopisa melt coating process ndeye preheating tembiricha yeworkpiece. Kana tembiricha yepreheating yakanyanya kukwira, inogona kukonzera yakanyanya oxidation yesimbi, kuderedza kunamatira kwejasi, uye inogona kutokonzeresa kuora kweresin uye kupupa kana kushanduka kwemavara. Kana tembiricha yepreheating yakadzikira, resin haina kuyerera zvakanaka, zvichiita kuti zviome kuwana jira rakafanana. Kazhinji, kupfapfaidza kumwe chete kweiyo inopisa melt coating nzira haigone kuwana ukobvu hunodiwa, saka kupfapfaidza kwakawanda kunodiwa. Mushure mega yega yekupfapfaidza application, kupisa kurapwa kunofanirwa kunyungudika zvachose uye kuvhenekesa iyo yekuputira usati waisa yechipiri layer. Izvi hazvingovimbisi yunifomu uye yakatsetseka coating asiwo zvakanyanya kunatsiridza iyo mechanical simba. Iyo inokurudzirwa kupisa tembiricha yekupisa ye polyethylene yakakwira-density inosvika 170°C, uye yechlorinated polyether, inotenderera 200°C, nenguva inokurudzirwa yeawa imwe chete.

Iyo inopisa yakanyunguduka yekuputira nzira inoburitsa yakakwirira-mhando, inoyevedza inoyevedza, yakasimba yakasungirirwa machira ane kushoma resin kurasikirwa. Zviri nyore kudzora, ine kunhuhwirira kushoma, uye pfuti yekupfapfaidza inoshandiswa inoita.

Dzimwe nzira dziripo dzepurasitiki yekupfekedza simbi

1. Kupfapfaidza: Zadza kumiswa mumudziyo wepfuti yekupfapfaidza uye shandisa mweya wakadzvanywa negeji yekumanikidza isingapfuuri 0.1 MPa kuti imwaya zvakaenzana coating pamusoro peiyo workpiece. Kuti uderedze kurasikirwa kwekumisa, mhepo yemhepo inofanira kuchengetwa yakaderera sezvinobvira. Nharaunda pakati pe workpiece uye nozzle inofanira kuchengetedzwa pa 10-20 cm, uye nzvimbo yekupfapfaidza inofanira kuchengetwa perpendicular kune kutungamira kwekuyerera kwezvinhu.

2. Kunyudzwa: Nyura iyo workpiece mukumiswa kwemasekonzi mashoma, wozoibvisa. Panguva ino, dhizaini yekumisa inonamatira kumusoro kweiyo workpiece, uye yakawandisa mvura inogona kuyerera ichidzika. Iyi nzira yakakodzera kune madiki-saizi workpieces inoda kuzara yakazara pamusoro pekunze.

3. Brushing: Kubhurasha kunosanganisira kushandisa bhurashi repende kana bhurashi kuti uise kusungirirwa pamusoro pebasa rekushanda, kugadzira jira. Kubhurasha kwakakodzera kune generalized coating kana single-sided coating pane nhete. Nekudaro, haiwanzo shandiswa nekuda kweiyo inokonzeresa kushoma uye kunyange kumusoro mushure mekuputirwa nekuomeswa, uye kuganhurirwa pahukobvu hwega hwega hwekuputira layer.

4. Kudururira: Dururira kusungirirwa mubato rinotenderera rekushanda, kuve nechokwadi kuti mukati memukati wakafukidzwa zvachose nekumiswa. Zvadaro, durura mvura yakawandisa kuti uite chifukidzo. Iyi nzira yakakodzera kupfekedza madiki reactors, mapaipi, magokora, mavharuvhu, pombi casings, tees, uye zvimwe zvakafanana workpieces.

ndiri kutsvaga thermoplastic coatings yewaya yesimbi

Iyi saiti yepaindaneti ndiyo yandinofema mukati, yakanaka dhizaini uye zvakakwana zvemukati.

Ndinofunga kuti iyi ndeimwe yeruzivo rwakakosha kwandiri. Uye ndinofara kuverenga chinyorwa chako. Asi kuda kutaura pazvinhu zvishoma zvakajairwa, Kuravira kwesaiti kwakakwana, zvinyorwa zvacho ndezvechokwadi: D. Basa rakanaka, cheers