Yas Txheej Rau Hlau

Cov txheej txheem txheej txheem hlau yog siv cov txheej txheem ntawm cov yas rau ntawm qhov chaw ntawm cov hlau, uas tso cai rau lawv khaws cov yam ntxwv ntawm cov hlau thaum tseem muab qee yam khoom ntawm cov yas, xws li corrosion kuj, hnav tsis kam, hluav taws xob rwb thaiv tsev, thiab nws tus kheej. -lubrication. Cov txheej txheem no yog qhov tseem ceeb hauv kev nthuav dav daim ntawv thov ntau yam ntawm cov khoom thiab txhim kho lawv cov txiaj ntsig kev lag luam.

Cov txheej txheem yas txheej rau hlau

Muaj ntau txoj hauv kev rau cov txheej txheem yas, nrog rau cov nplaim hluav taws, fluidized txaj tshuaj tsuag, hmoov electrostatic txau, kub yaj txheej, thiab ncua txheej txheej. Kuj tseem muaj ntau hom yas uas tuaj yeem siv rau txheej, nrog PVC, PE, thiab PA feem ntau siv. Cov yas siv rau txheej yuav tsum yog hmoov, nrog rau qhov zoo ntawm 80-120 mesh.

Tom qab txheej, nws yog qhov zoo tshaj plaws kom txias lub workpiece los ntawm immersing nws nyob rau hauv dej txias. Kev ua kom txias nrawm tuaj yeem txo cov crystallinity ntawm cov yas txheej, ua kom cov dej ntau ntxiv, txhim kho qhov toughness thiab ci ntsa iab ntawm cov txheej txheej, ua kom adhesion, thiab kov yeej txheej txheej detachment los ntawm kev ntxhov siab sab hauv.

Txhawm rau txhim kho qhov adhesion ntawm cov txheej thiab cov hlau hauv paus, qhov chaw ntawm lub workpiece yuav tsum tsis muaj plua plav thiab qhuav, tsis muaj xeb thiab roj ua ntej txheej. Feem ntau, lub workpiece yuav tsum tau kho saum npoo. Cov kev kho mob muaj xws li sandblasting, tshuaj kho mob, thiab lwm yam kev siv tshuab. Ntawm lawv, sandblasting muaj cov teebmeem zoo dua vim nws roughens qhov chaw ntawm lub workpiece, ua rau thaj tsam ntawm qhov chaw thiab tsim hooks, yog li txhim kho adhesion. Tom qab sandblasting, lub workpiece nto yuav tsum tau tshuab nrog huv compressed cua kom tshem tawm cov plua plav, thiab cov yas yuav tsum tau coated nyob rau hauv 6 teev, txwv tsis pub, lub nto yuav oxidize, cuam tshuam rau adhesion ntawm txheej.

Advantage

Direct txheej nrog hmoov yas muaj cov hauv qab no zoo:

- Nws tuaj yeem siv nrog cov resins uas tsuas muaj nyob rau hauv cov hmoov hmoov.

- Ib txheej tuab tuaj yeem tau txais hauv ib daim ntawv thov.

- Cov khoom uas muaj cov duab nyuaj lossis cov npoo ntse tuaj yeem coated zoo.

- Feem ntau cov hmoov plastics muaj kev ruaj ntseg zoo heev.

- Tsis xav tau cov kuab tshuaj, ua cov txheej txheem npaj cov khoom yooj yim. Txawm li cas los xij, kuj tseem muaj qee qhov tsis zoo lossis kev txwv rau cov hmoov txheej. Piv txwv li, yog tias lub workpiece xav tau preheated, nws qhov loj me yuav raug txwv. Vim tias txheej txheej txheej txheej yuav siv sij hawm, rau qhov loj-loj workpieces, thaum txau tseem tsis tau tiav, qee qhov chaw twb tau txias hauv qab qhov kub thiab txias. Thaum lub sij hawm cov txheej txheem yas hmoov txheej, hmoov poob tuaj yeem siab txog 60%, yog li nws yuav tsum tau sau thiab rov siv dua kom tau raws li kev lag luam.

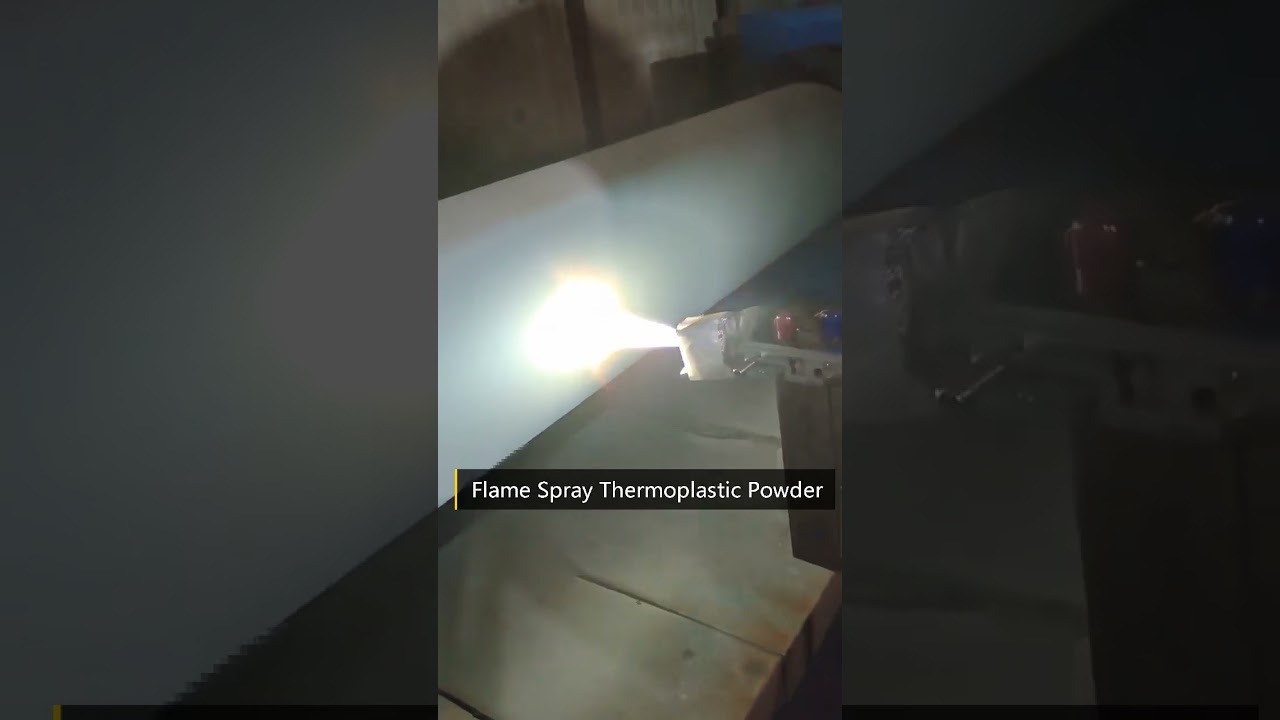

Nplaim Txau

Nplaim tshuaj tsuag yas txheej rau hlau yog txheej txheem uas muaj melting los yog ib nrab melting hmoov los yog pasty yas nrog ib tug nplaim taws tawm los ntawm ib rab phom, thiab ces txau cov yas molten rau saum npoo ntawm ib yam khoom los ua ib tug yas txheej. Lub thickness ntawm txheej yog feem ntau ntawm 0.1 thiab 0.7 hli. Thaum siv cov hmoov yas rau nplaim hluav taws, lub workpiece yuav tsum tau preheated. Preheating tuaj yeem ua tiav hauv qhov cub, thiab qhov kub ntawm preheating txawv depending ntawm hom yas raug txau.

Cov nplaim kub thaum lub sij hawm txau yuav tsum tau tswj nruj me ntsis, vim tias qhov kub thiab txias tuaj yeem kub hnyiab lossis ua rau cov yas puas, thaum qhov kub thiab txias heev tuaj yeem cuam tshuam rau adhesion. Feem ntau, qhov kub thiab txias yog qhov siab tshaj plaws thaum txau thawj txheej ntawm cov yas, uas tuaj yeem txhim kho adhesion ntawm cov hlau thiab yas. Raws li cov khaubncaws sab nraud povtseg tom ntej, qhov kub tuaj yeem txo qis me ntsis. Qhov kev ncua deb ntawm rab phom txau thiab cov khoom ua haujlwm yuav tsum yog ntawm 100 thiab 200 cm. Rau cov workpieces tiaj tus, lub workpiece yuav tsum tau muab tso rau hauv kab rov tav thiab rab phom tsuag yuav tsum tau txav mus los; rau cylindrical los yog internal bore workpieces, lawv yuav tsum tau mounted rau ntawm lub tshuab dhos rau rotational txau. Lub linear ceev ntawm rotating workpiece yuav tsum nyob nruab nrab ntawm 20 thiab 60 m / min. Tom qab qhov xav tau ntawm cov txheej txheej tiav lawm, cov tshuaj tsuag yuav tsum tau nres thiab lub workpiece yuav tsum tig mus ntxiv kom txog thaum cov yas molten solidifies, thiab tom qab ntawd nws yuav tsum tau txias sai.

Txawm hais tias cov nplaim hluav taws xob muaj qhov ua tau zoo ntawm cov khoom siv hluav taws xob tsawg thiab suav nrog kev siv cov pa roj carbon monoxide, nws tseem yog ib txoj hauv kev ua haujlwm tseem ceeb hauv kev lag luam vim nws cov cuab yeej siv qis thiab kev ua tau zoo hauv txheej txheej sab hauv ntawm cov tso tsheb hlau luam, ntim, thiab cov khoom ua haujlwm loj piv rau lwm txoj hauv kev. .

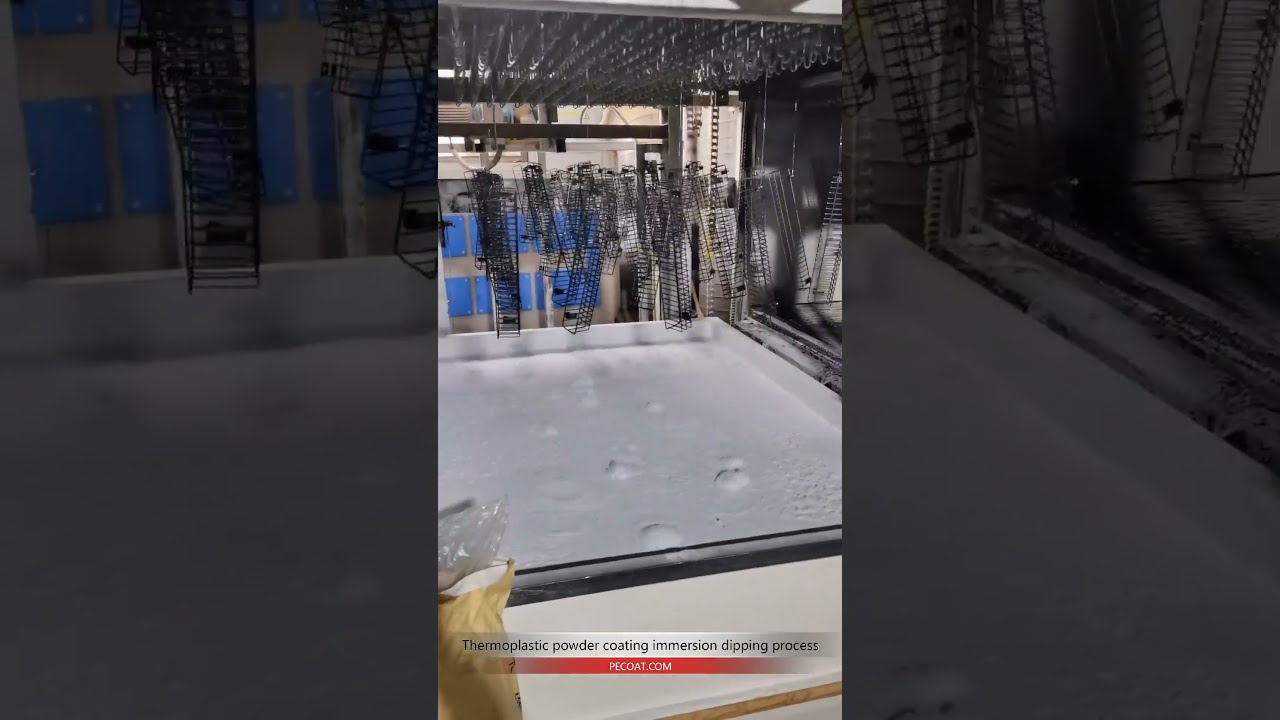

Fluidized-bed Dip Yas Txheej

Lub hauv paus ntsiab lus ntawm kev ua hauj lwm ntawm fluidized txaj dip yas txheej rau hlau yog raws li nram no: yas txheej hmoov yog muab tso rau hauv ib lub thawv cylindrical nrog ib tug ntxeem tau muab faib nyob rau sab saum toj uas tso cai rau tsuas yog huab cua dhau mus, tsis yog hmoov. Thaum cov cua compressed nkag los hauv qab ntawm lub thawv, nws tshuab cov hmoov thiab tshem tawm hauv lub thawv. Yog hais tias lub workpiece preheated yog immersed nyob rau hauv nws, cov resin hmoov yuav yaj thiab ua raws li lub workpiece, tsim ib txheej.

Lub thickness ntawm txheej tau nyob rau hauv fluidized txaj depends ntawm qhov kub thiab txias, lub peev xwm kub tshwj xeeb, coefficient ntawm qhov chaw, lub sij hawm tshuaj tsuag, thiab hom yas siv thaum lub workpiece nkag mus rau hauv lub chamber fluidized. Txawm li cas los xij, tsuas yog qhov kub thiab txau lub sij hawm ntawm lub workpiece tuaj yeem tswj tau hauv cov txheej txheem, thiab lawv yuav tsum tau txiav txim siab los ntawm kev sim hauv kev tsim khoom.

Thaum lub sij hawm dipping, nws yuav tsum tau hais tias cov hmoov yas ntws zoo thiab tusyees, tsis muaj agglomeration, vortex flow, los yog ntau dispersion ntawm cov khoom yas. Cov kev ntsuas sib xws yuav tsum tau ua kom ua tau raws li cov cai no. Ntxiv cov cuab yeej nplawm tuaj yeem txo cov agglomeration thiab vortex ntws, thaum ntxiv me me ntawm cov hmoov talcum rau cov hmoov yas yog qhov zoo rau cov kua dej, tab sis nws yuav cuam tshuam rau qhov zoo ntawm cov txheej. Txhawm rau tiv thaiv kev tawg ntawm cov khoom yas, cov cua ntws thiab qhov sib xws ntawm cov hmoov yas yuav tsum tau tswj nruj me ntsis. Txawm li cas los xij, qee qhov kev tsis sib haum xeeb yog qhov tsis tuaj yeem, yog li cov cuab yeej rov qab yuav tsum tau nruab rau sab saud ntawm lub txaj fluidized.

Qhov zoo ntawm fluidized txaj dip yas txheej yog lub peev xwm los coated complex-shaped workpieces, siab txheej zoo, tau ib tug thicker txheej nyob rau hauv ib daim ntawv thov, tsawg resin poob, thiab ib tug huv si chaw ua hauj lwm. Qhov tsis zoo yog qhov nyuaj ntawm kev ua cov khoom loj loj.

Electrostatic txau yas txheej rau hlau

Nyob rau hauv electrostatic txau, resin yas txheej hmoov yog tsau rau saum npoo ntawm lub workpiece los ntawm electrostatic quab yuam, es tsis yog los ntawm melting los yog sintering. Lub hauv paus ntsiab lus yog siv lub tshuab hluav taws xob electrostatic tsim los ntawm high-voltage electrostatic generator kom them cov hmoov resin txau los ntawm cov phom tsuag nrog hluav taws xob zoo li qub, thiab cov khoom siv hauv av yuav dhau los ua cov hluav taws xob zoo electrode. Yog li ntawd, ib txheej ntawm cov hmoov yas tsis sib xws sai sai tso rau ntawm qhov chaw ntawm lub workpiece. Ua ntej tus nqi dissipates, hmoov txheej adheres khov kho. Tom qab cua sov thiab cua txias, cov txheej txheem yas tuaj yeem tau txais.

Hmoov electrostatic txau yog tsim nyob rau hauv nruab nrab-1960s thiab yooj yim rau automate. Yog tias cov txheej tsis tas yuav tsum yog tuab, electrostatic txau tsis tas yuav tsum tau preheating ntawm workpiece, yog li nws tuaj yeem siv rau cov khoom siv hluav taws xob lossis cov khoom ua haujlwm uas tsis haum rau cua sov. Nws kuj tsis tas yuav muaj lub thawv ntim loj, uas yog qhov tseem ceeb hauv kev txau cov txaj fluidized. Cov hmoov uas hla lub workpiece yog attracted rau tom qab ntawm lub workpiece, yog li tus nqi ntawm overspray yog ntau npaum li cas tsawg tshaj li nyob rau hauv lwm txoj kev txau, thiab tag nrho cov workpiece yuav coated los ntawm txau rau ntawm ib sab. Txawm li cas los xij, cov khoom loj loj tseem yuav tsum tau txau ntawm ob sab.

Cov khoom ua haujlwm nrog cov ntu sib txawv tuaj yeem tsim teeb meem rau cov cua sov tom qab. Yog tias qhov sib txawv ntawm ntu ntu loj dhau lawm, qhov tuab ntawm cov txheej txheej yuav tsis ncav cuag qhov kub thiab txias, thaum lub thinner feem yuav tau yaj lossis degraded. Nyob rau hauv cov ntaub ntawv no, lub thermal stability ntawm cov resin yog ib qho tseem ceeb.

Cheebtsam nrog zoo zoo sab hauv cov ces kaum thiab qhov tob yog tsis yooj yim them los ntawm electrostatic txau vim hais tias cov cheeb tsam no muaj electrostatic shielding thiab repel cov hmoov, thaiv cov txheej txheem los ntawm kev nkag mus rau hauv cov ces kaum lossis qhov tshwj tsis yog tias rab phom tuaj yeem tso rau hauv lawv. Tsis tas li ntawd, electrostatic spraying yuav tsum tau finer particles vim hais tias loj dua yuav detach lub workpiece, thiab hais finer tshaj 150 mesh yog zoo dua nyob rau hauv electrostatic kev txiav txim.

Kub yaj txheej txheej txheem

Lub hauv paus ntsiab lus ntawm kev ua haujlwm ntawm cov txheej txheem kub yaj yog txau cov hmoov txheej txheej rau hauv qhov chaw ua haujlwm preheated siv rab phom tsuag. Cov yas yaj los ntawm kev siv cov cua sov ntawm cov khoom ua haujlwm, thiab tom qab txias, cov txheej yas tuaj yeem siv rau ntawm qhov chaw ua haujlwm. Yog tias tsim nyog, kev kho cua sov tom qab kuj tseem xav tau.

Tus yuam sij rau kev tswj cov txheej txheem kub yaj txheej yog lub preheating kub ntawm workpiece. Thaum lub preheating kub siab dhau lawm, nws tuaj yeem ua rau oxidation hnyav ntawm cov hlau nto, txo qhov adhesion ntawm txheej, thiab tej zaum yuav ua rau resin decomposition thiab foaming los yog discoloration ntawm txheej. Thaum qhov kub ntawm preheating tsawg dhau, cov resin muaj cov dej ntws tsis zoo, ua rau nws nyuaj kom tau txais cov txheej txheem sib xws. Feem ntau, ib daim ntawv thov ntawm cov txheej txheem kub yaj txheej tsis tuaj yeem ua tiav cov thickness xav tau, yog li yuav tsum tau siv ntau yam tshuaj tsuag. Tom qab txhua daim ntawv thov tshuaj tsuag, kev kho cua sov yog tsim nyog kom yaj tag thiab ci lub txheej ua ntej thov txheej thib ob. Qhov no tsis tsuas yog ua kom cov txheej txheem sib xws thiab du, tab sis kuj tseem txhim kho cov neeg kho tshuab lub zog. Qhov pom zoo rau kev kho cua sov kub rau high-density polyethylene yog nyob ib ncig ntawm 170 ° C, thiab rau chlorinated polyether, nws yog nyob ib ncig ntawm 200 ° C, nrog rau lub sij hawm pom zoo ntawm 1 teev.

Cov txheej txheem kub yaj txheej ua rau cov khoom zoo, zoo nkauj txaus nyiam, sib koom ua ke nrog cov txheej txheem tsawg kawg nkaus. Nws yog ib qho yooj yim los tswj, muaj ntxhiab tsw tsawg, thiab cov tshuaj tsuag siv tau ua.

Lwm txoj hauv kev muaj rau cov yas txheej rau hlau

1. Txau: Sau cov kev ncua mus rau hauv rab phom phom reservoir thiab siv cov cua compressed nrog lub ntsuas siab tsis tshaj 0.1 MPa kom sib npaug ntawm cov txheej txheej rau ntawm qhov chaw ua haujlwm. Txhawm rau txo qhov kev ncua kev poob qis, huab cua siab yuav tsum tau khaws cia kom tsawg li sai tau. Qhov kev ncua deb ntawm lub workpiece thiab lub nozzle yuav tsum tau khaws cia ntawm 10-20 cm, thiab cov tshuaj tsuag yuav tsum tau muab cia rau perpendicular mus rau cov kev taw qhia ntawm cov khoom ntws.

2. Immersion: Raus lub workpiece nyob rau hauv lub ncua kev kawm ntawv rau ob peb feeb, ces tshem tawm nws. Nyob rau lub sijhawm no, ib txheej ntawm kev ncua yuav ua raws li qhov chaw ntawm lub workpiece, thiab cov kua dej ntau dhau tuaj yeem ntws mus ib txwm. Txoj kev no yog tsim rau me me workpieces uas yuav tsum tau ua kom tiav txheej ntawm sab nraud.

3. Kev txhuam hniav: Kev txhuam hniav yog siv cov txhuam hniav los yog txhuam hniav los siv cov kev ncua mus rau qhov chaw ntawm qhov chaw ua haujlwm, tsim cov txheej txheem. Txhuam yog tsim rau cov txheej txheem hauv cheeb tsam lossis ib sab txheej ntawm qhov nqaim. Txawm li cas los xij, nws tsis tshua siv vim qhov tshwm sim tsawg dua thiab txawm tias ntog tom qab txheej txheej qhuav, thiab kev txwv ntawm cov tuab ntawm txhua txheej txheej.

4. Pouring: Ncuav lub ncua kev kawm ntawv mus rau hauv ib tug rotating hollow workpiece, xyuas kom meej tias lub puab nto yog kiag li npog los ntawm lub suspension. Tom qab ntawd, ncuav tawm cov kua ntau dhau los ua ib txheej txheej. Txoj kev no yog tsim rau txheej me me reactors, pipelines, luj tshib, li qub, twj tso kua mis, tees, thiab lwm yam workpieces zoo sib xws.

Kuv tab tom nrhiav thermoplastic txheej rau hlau hlau

Qhov chaw hauv internet no yog kuv ua pa, zoo heev layout thiab zoo meej cov ntsiab lus.

Kuv xav tias qhov no yog ib qho ntawm cov ntaub ntawv tseem ceeb heev rau kuv. Thiab kuv zoo siab nyeem koj tsab xov xwm. Tab sis xav hais rau ob peb yam ib txwm, Lub site saj yog zoo meej, cov khoom yog nyob rau hauv kev muaj tiag zoo: D. Ua hauj lwm zoo, cheers