Kupaka Pulasitiki Kwa Chitsulo

Pulasitiki ❖ kuyanika kwa ndondomeko zitsulo ndi ntchito wosanjikiza pulasitiki pamwamba pa zitsulo mbali zitsulo, amene amalola kusunga makhalidwe oyambirira a zitsulo ndi kupereka zinthu zina za pulasitiki, monga kukana dzimbiri, kuvala kukana, kutchinjiriza magetsi, ndi kudzikonda. -mafuta. Njira iyi ndi yofunika kwambiri pakukulitsa kuchuluka kwa zinthu zomwe zimagwiritsidwa ntchito komanso kukulitsa phindu lawo pazachuma.

Njira zokutira pulasitiki zitsulo

Pali njira zambiri zokutira pulasitiki, kuphatikiza kupopera mbewu pamoto, fluidized bed kupopera mbewu mankhwalawa, kupopera ufa electrostatic, otentha Sungunulani ❖ kuyanika, ndi kuyimitsidwa ❖ kuyanika. Palinso mitundu yambiri ya mapulasitiki omwe angagwiritsidwe ntchito kupaka, ndi PVC, PE, ndi PA kukhala omwe amagwiritsidwa ntchito kwambiri. Pulasitiki yomwe imagwiritsidwa ntchito popaka iyenera kukhala yaufa, yokhala ndi ma mesh 80-120.

Pambuyo kupaka, ndi bwino kuziziritsa mwamsanga workpiece ndi kumizidwa m'madzi ozizira. Kuzizira kofulumira kumatha kuchepetsa kristalo wa zokutira pulasitiki, kuonjezera madzi, kumapangitsanso kulimba ndi kuwala kwa pamwamba pa zokutira, kuonjezera kumamatira, ndikugonjetsa kutsekedwa kwa zokutira chifukwa cha kupsinjika kwa mkati.

Kupititsa patsogolo kumamatira pakati pa zokutira ndi zitsulo zoyambira, pamwamba pa chogwiriracho chiyenera kukhala chopanda fumbi komanso chowuma, popanda dzimbiri ndi mafuta musanaphike. Nthawi zambiri, workpiece imayenera kuthandizidwa pamwamba. Njira zochizira zimaphatikizapo kupukuta mchenga, mankhwala opangira mankhwala, ndi njira zina zamakina. Pakati pawo, kuphulika kwa mchenga kumakhala ndi zotsatira zabwino chifukwa kumapangitsa kuti pakhale phokoso pamwamba pa workpiece, kuonjezera malo ndi kupanga mbedza, motero kumawonjezera kumamatira. Pambuyo pa sandblasting, malo ogwirira ntchito amayenera kuwomberedwa ndi mpweya wabwino wothinikizidwa kuti achotse fumbi, ndipo pulasitiki iyenera kuphimbidwa mkati mwa maola 6, apo ayi, pamwamba pamakhala oxidize, zomwe zimakhudza kumamatira kwa zokutira.

ubwino

Kuphimba mwachindunji ndi pulasitiki yaufa kuli ndi ubwino wotsatirawu:

- Itha kugwiritsidwa ntchito ndi utomoni womwe umapezeka mu mawonekedwe a ufa.

- Chophimba chakuda chikhoza kupezeka mu ntchito imodzi.

- Zogulitsa zokhala ndi mawonekedwe ovuta kapena m'mbali zakuthwa zimatha kukutidwa bwino.

- Mapulasitiki ambiri a ufa amakhala ndi kukhazikika bwino kosungirako.

- Palibe zosungunulira zomwe zimafunikira, kupanga njira yokonzekera zinthu kukhala yosavuta. Komabe, palinso zovuta zina kapena zolepheretsa pakupaka ufa. Mwachitsanzo, ngati workpiece iyenera kutenthedwa, kukula kwake kudzakhala kochepa. Chifukwa ❖ kuyanika kumatenga nthawi, kwa zogwirira ntchito zazikuluzikulu, pamene kupopera mbewu mankhwalawa sikunathe, madera ena azizira kale pansi pa kutentha kofunikira. Panthawi yopaka pulasitiki ya ufa, kutayika kwa ufa kumatha kufika 60%, choncho kuyenera kusonkhanitsidwa ndikugwiritsidwanso ntchito kukwaniritsa zofunikira zachuma.

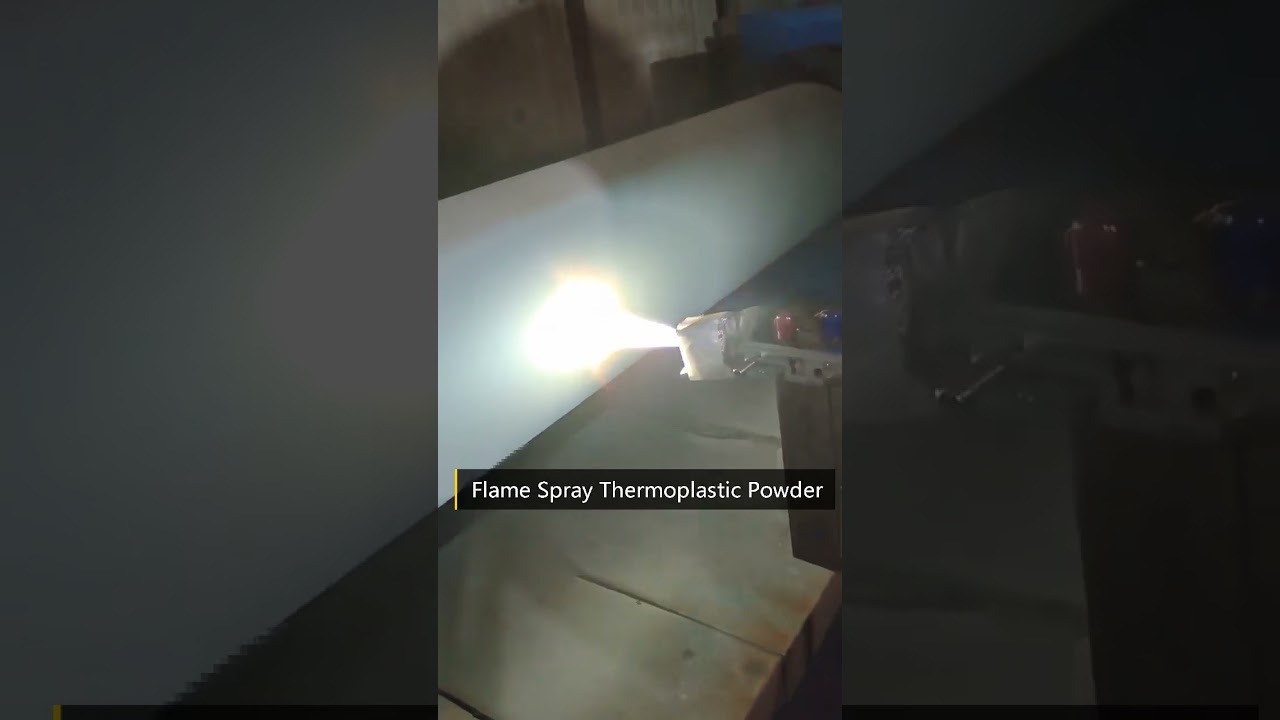

Kupopera kwa Lawi

Kupaka pulasitiki kwamoto ndi njira yomwe imaphatikizapo kusungunula kapena kusungunula pang'ono pulasitiki ya ufa kapena pasty yokhala ndi lawi lochokera mumfuti yopopera, ndiyeno kupopera pulasitiki yosungunuka pamwamba pa chinthu kupanga zokutira pulasitiki. Makulidwe a zokutira nthawi zambiri amakhala pakati pa 0.1 ndi 0.7 mm. Mukamagwiritsa ntchito pulasitiki yaufa kupopera moto, chogwirira ntchito chiyenera kutenthedwa. Kutenthetsa kutha kuchitidwa mu uvuni, ndipo kutentha kwa preheat kumasiyanasiyana depekuyang'ana pa mtundu wa pulasitiki womwe ukupopera.

Kutentha kwa lawi pa kupopera mbewu mankhwalawa kuyenera kuyendetsedwa mosamalitsa, chifukwa kutentha kwambiri kumatha kuwotcha kapena kuwononga pulasitiki, pomwe kutentha kwambiri kumatha kukhudza kumamatira. Nthawi zambiri, kutentha kumakhala kokwera kwambiri popopera mbewu mankhwalawa gawo loyamba la pulasitiki, lomwe limatha kuwongolera kumamatira pakati pa chitsulo ndi pulasitiki. Pamene zigawo zotsatila zimapopera, kutentha kumatha kuchepetsedwa pang'ono. Mtunda pakati pa mfuti ya spray ndi workpiece uyenera kukhala pakati pa 100 ndi 200 cm. Pazogwiritsira ntchito lathyathyathya, zogwirira ntchito ziyenera kuyikidwa mozungulira ndipo mfuti yopopera iyenera kusunthidwa mmbuyo ndi mtsogolo; kwa cylindrical kapena mkati anabowo workpieces, iwo wokwera pa lathe kupopera mozungulira. Kuthamanga kwa mzere wozungulira wa workpiece kuyenera kukhala pakati pa 20 ndi 60 m / min. Pambuyo pa makulidwe ofunikira a zokutira akwaniritsidwa, kupopera mbewu mankhwalawa kuyenera kuyimitsidwa ndipo chogwirira ntchito chiyenera kupitilizabe kusinthasintha mpaka pulasitiki yosungunuka itakhazikika, ndiyeno iyenera kukhazikika mwachangu.

Ngakhale lawi kupopera ali ndi mphamvu otsika kupanga ndi kumaphatikizapo ntchito mpweya wokwiyitsa, akadali njira yofunika processing makampani chifukwa otsika zida ndalama ndi mogwira ❖ kuyanika Interiors akasinja, muli, ndi workpieces lalikulu poyerekeza ndi njira zina. .

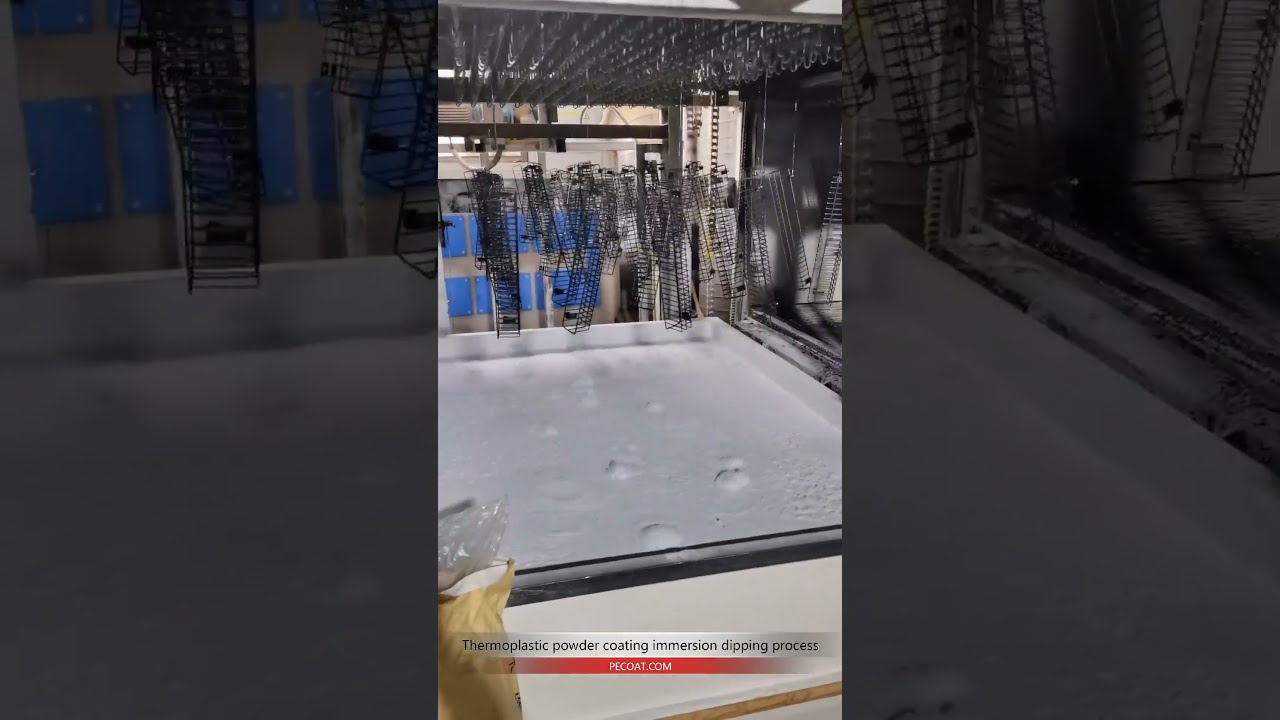

Fluidized-bed Dip Plastic Coating

Mfundo ntchito fluidized bedi kuviika pulasitiki ❖ kuyanika zitsulo ndi motere: pulasitiki ❖ kuyanika ufa amaikidwa mu chidebe cylindrical ndi porous kugawa pamwamba kuti amalola mpweya kudutsa, osati ufa. Mpweya wopanikizidwa ukalowa kuchokera pansi pa chidebecho, umawuzira ufawo ndikuuyimitsa mu chidebecho. Ngati workpiece preheated kumizidwa mmenemo, utomoni ufa adzasungunuka ndi kumamatira workpiece, kupanga zokutira.

Kuchuluka kwa zokutira zomwe zimapezeka pabedi lothira madzi depends pa kutentha, kutentha kwapadera mphamvu, pamwamba coefficient, kutsitsi nthawi, ndi mtundu wa pulasitiki ntchito pamene workpiece alowa m'chipinda fluidized. Komabe, kutentha ndi nthawi yopopera yokha ya workpiece ikhoza kulamulidwa panthawiyi, ndipo imayenera kutsimikiziridwa ndi kuyesa pakupanga.

Pa kuviika, pamafunika kuti ufa wa pulasitiki umayenda bwino komanso wofanana, popanda agglomeration, vortex otaya, kapena kubalalitsidwa kwakukulu kwa tinthu tapulasitiki. Njira zofananira ziyenera kuchitidwa kuti zikwaniritse zofunikira izi. Kuonjezera chipangizo chotsitsimutsa kungachepetse agglomeration ndi vortex flow, pamene kuwonjezera pang'ono ufa wa talcum ku ufa wa pulasitiki ndi wopindulitsa kwa fluidization, koma zingakhudze ubwino wa zokutira. Pofuna kupewa kubalalitsidwa kwa tinthu tating'onoting'ono ta pulasitiki, kuchuluka kwa mpweya komanso kufanana kwa tinthu tating'ono ta pulasitiki kuyenera kuyendetsedwa mosamalitsa. Komabe, kubalalitsidwa kwina sikungapeweke, kotero chipangizo chobwezeretsa chiyenera kuikidwa kumtunda kwa bedi lamadzimadzi.

Ubwino wa zokutira zapulasitiki zamadzimadzi ndikutha kuvala zomangira zowoneka bwino, zokutira zapamwamba kwambiri, kupeza zokutira zokulirapo pakugwiritsa ntchito kamodzi, kutayika kochepa kwa utomoni, komanso malo oyera ogwirira ntchito. Choyipa chake ndizovuta kukonza ma workpieces akuluakulu.

Electrostatic kupopera mbewu mankhwalawa pulasitiki wokutira zitsulo

Mu kupopera mankhwala electrostatic, utomoni ❖ kuyanika ufa ufa wokhazikika pamwamba pa workpiece ndi electrostatic mphamvu, osati ndi kusungunuka kapena sintering. Mfundo ndi ntchito electrostatic munda wopangidwa ndi mkulu-voteji electrostatic jenereta kuti azilipiritsa utomoni ufa sprayed kuchokera kutsitsi mfuti ndi magetsi malo amodzi, ndi workpiece pansi amakhala mkulu-voteji zabwino elekitirodi. Chotsatira chake, wosanjikiza wa ufa yunifolomu pulasitiki mwamsanga madipoziti pamwamba pa workpiece. Malipiro asanayambe kutha, ufa wosanjikiza umamatira mwamphamvu. Pambuyo pa kutentha ndi kuzizira, chophimba cha pulasitiki chofanana chikhoza kupezeka.

Ufa electrostatic kupopera mbewu mankhwalawa anapangidwa m'ma 1960s ndipo n'zosavuta automate. Ngati ❖ kuyanika sayenera wandiweyani, kupopera mankhwala electrostatic sikutanthauza preheating wa workpiece, choncho angagwiritsidwe ntchito zipangizo kutentha tcheru kapena workpieces kuti si oyenera Kutentha. Komanso sikutanthauza lalikulu yosungirako chidebe, amene n'kofunika fluidized bedi kupopera mbewu mankhwalawa. Ufa umene umadutsa pa workpiece umakopeka kumbuyo kwa workpiece, kotero kuti kuchuluka kwa overspray kumakhala kochepa kwambiri kusiyana ndi njira zina zopopera mankhwala, ndipo workpiece yonse ikhoza kukutidwa ndi kupopera mbewu mankhwalawa mbali imodzi. Komabe, zogwirira ntchito zazikulu zimafunikirabe kupopera mbali zonse ziwiri.

Zopangira zokhala ndi magawo osiyanasiyana zimatha kukhala zovuta pakuwotha kotsatira. Ngati kusiyana pakati pa mtanda ndi kwakukulu kwambiri, mbali yowonjezereka ya chophimbacho sichikhoza kufika kutentha kosungunuka, pamene gawo lochepa kwambiri likhoza kusungunuka kale kapena kuwonongeka. Pankhaniyi, kukhazikika kwamafuta a utomoni ndikofunikira.

Zigawo zokhala ndi ngodya zabwino zamkati ndi mabowo akuya sizikuphimbidwa mosavuta ndi kupopera mbewu mankhwalawa chifukwa maderawa ali ndi chitetezo chamagetsi ndi r.epel ufa, kulepheretsa zokutira kuti zilowe m'makona kapena mabowo pokhapokha ngati mfuti yopopera ingalowetsedwemo. Komanso, kupopera mbewu mankhwalawa kumafuna tinthu tating'onoting'ono chifukwa tinthu tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono tating'onoting'ono ta 150 ma mesh ndiabwino kwambiri pakuchita electrostatic.

Njira yokutira yotentha yosungunuka

Mfundo yogwiritsira ntchito njira yoyakira yotentha ndi kupopera ufa wa pulasitiki pazitsulo zotenthetserapo pogwiritsa ntchito mfuti ya spray. Pulasitiki imasungunuka pogwiritsa ntchito kutentha kwa chogwirira ntchito, ndipo pambuyo pozizira, zokutira zapulasitiki zitha kuyikidwa pachogwirira ntchito. Ngati ndi kotheka, pambuyo Kutentha mankhwala chofunikanso.

Chinsinsi chowongolera njira yoyatsira yotentha ndi kutentha kwa preheating kwa workpiece. Kutentha kwa preheating ndikwambiri, kumatha kuyambitsa okosijeni wambiri pamwamba pazitsulo, kuchepetsa kumamatira kwa zokutira, ndipo kungayambitse kuwonongeka kwa utomoni ndi kutulutsa thovu kapena kusinthika kwa zokutira. Kutentha kwa preheating ndi kotsika kwambiri, utomoni umakhala wosasunthika bwino, zomwe zimapangitsa kuti zikhale zovuta kupeza zokutira zofananira. Nthawi zambiri, kupopera kamodzi kwa njira yoyakira yotentha yosungunuka sikungakwaniritse makulidwe omwe mukufuna, chifukwa chake pamafunika kupopera kangapo. Pambuyo pa ntchito iliyonse yopopera, chithandizo cha kutentha chiyenera kusungunuka kwathunthu ndi kuwunikira ❖ kuyanika musanagwiritse ntchito gawo lachiwiri. Izi sizimangotsimikizira kuti yunifolomu ndi yosalala ❖ kuyanika komanso kumapangitsanso kwambiri mphamvu zamakina. Kutentha kovomerezeka kwa kutentha kwa polyethylene wochuluka kwambiri ndi pafupifupi 170 ° C, ndipo pa polyether ya chlorinated, ndi pafupi 200 ° C, ndi nthawi yovomerezeka ya ola limodzi.

Njira yopaka yotentha yosungunuka imapanga zokutira zapamwamba kwambiri, zokometsera, zomangika mwamphamvu ndi kutaya pang'ono kwa utomoni. Ndizosavuta kuzilamulira, zimakhala ndi fungo lochepa, ndipo mfuti yopopera yomwe imagwiritsidwa ntchito imatero.

Njira zina zopangira pulasitiki zokutira zitsulo

1. Kupopera mbewu mankhwalawa: Lembani kuyimitsidwa mu nkhokwe yamfuti ndikugwiritsa ntchito mpweya woponderezedwa ndi mphamvu ya geji yosapitirira 0.1 MPa kuti mutsirize ❖ kuyanika pamwamba pa workpiece. Kuti muchepetse kuyimitsidwa kwa kuyimitsidwa, kuthamanga kwa mpweya kuyenera kuchepetsedwa momwe mungathere. Mtunda pakati pa workpiece ndi nozzle uyenera kusungidwa pa 10-20 cm, ndipo kupopera mbewu mankhwalawa kuyenera kusungidwa molingana ndi momwe zinthu zimayendera.

2. Kumiza: Imirira workpiece mu kuyimitsidwa kwa masekondi angapo, ndiye kuchotsa. Panthawiyi, kuyimitsidwa kumamatira pamwamba pa workpiece, ndipo madzi owonjezera amatha kutsika mwachibadwa. Njirayi ndi yoyenera kwazing'onozing'ono zogwirira ntchito zomwe zimafuna kupaka kwathunthu pamtunda wakunja.

3. Kutsuka: Kutsuka kumaphatikizapo kugwiritsa ntchito burashi ya penti kapena burashi kuti mugwiritse ntchito kuyimitsidwa pamwamba pa workpiece, kupanga zokutira. Kutsuka ndi koyenera ❖ kuyanika wamba kapena zokutira zambali imodzi pamalo opapatiza. Komabe, kawirikawiri amagwiritsidwa ntchito chifukwa chochepa chosalala komanso pamwamba pambuyo ❖ kuyanika ndi zouma, ndi malire pa makulidwe a aliyense ❖ kuyanika wosanjikiza.

4. Kuthira: Thirani kuyimitsidwa muzitsulo zozungulira zozungulira, kuonetsetsa kuti mkati mwake mwaphimbidwa ndi kuyimitsidwa. Kenaka, tsanulirani madzi owonjezera kuti mupange zokutira. Njirayi ndi yoyenera kupaka ma reactors ang'onoang'ono, mapaipi, zigongono, mavavu, ma casings apompo, ma tee, ndi zida zina zofananira.

ndikuyang'ana zokutira za thermoplastic za waya wachitsulo

Tsambali la intaneti ndilopumiramo, mawonekedwe abwino kwambiri komanso zinthu zabwino kwambiri.

Ndikuganiza kuti ichi ndi chimodzi mwazinthu zofunika kwambiri kwa ine. Ndipo ndine wokondwa kuwerenga nkhani yanu. Koma ndikufuna kunena pa zinthu zochepa wamba, Kukoma kwa tsambali ndikwabwino, zolembazo ndizabwino kwambiri: D. Ntchito yabwino, cheers