Ukugquma ngePlastiki kwiMetal

Iplastiki yokwambathisa inkqubo yesinyithi kukusebenzisa umaleko weplastiki kumphezulu wamalungu esinyithi, okubavumela ukuba bagcine iimpawu zantlandlolo zesinyithi ngelixa zibonelela ngeempawu ezithile zeplastiki, ezinjengokumelana nomhlwa, ukumelana nokunxiba, ukugqunywa kombane, kunye nokuzimela. -ukuthambisa. Le nkqubo ibaluleke kakhulu ekwandiseni uluhlu lwezicelo zeemveliso kunye nokuphucula ixabiso lezoqoqosho.

Iindlela zokugquma ngeplastiki yentsimbi

Zininzi iindlela zokugquma ngeplastiki, kuquka ukutshiza amadangatye, ibhedi emanzi ukutshiza, umgubo wokutshiza i-electrostatic, i-hot melt inyibiliko yokwambathisa, kunye ne-suspension coating. Kukho neentlobo ezininzi zeplastiki ezinokusetyenziselwa ukugquma, nge PVC, PE, kunye ne-PA yeyona isetyenziswa kakhulu. Iplastiki esetyenziselwa ukugquma kufuneka ibe ngumgubo, kunye ne-fineness ye-80-120 mesh.

Emva kokugubungela, kungcono ukupholisa ngokukhawuleza i-workpiece ngokuyintywilisela emanzini abandayo. Ukupholisa okukhawulezayo kunokunciphisa i-crystallinity ye-coating yeplastiki, ukwandisa umthamo wamanzi, ukuphucula ukuqina kunye nokukhanya kwendawo yokugubungela, ukwandisa ukunamathela, kunye nokweyisa i-coating detachment ebangelwa uxinzelelo lwangaphakathi.

Ukuphucula ukudibanisa phakathi kwengubo kunye nesiseko sesinyithi, ubuso bomsebenzi kufuneka bube buthuli kwaye bome, ngaphandle kokugqwala kunye negrisi ngaphambi kokugubungela. Kwiimeko ezininzi, i-workpiece ifuna ukunyangwa phezulu. Iindlela zonyango ziquka ukuqhunyiswa kwesanti, unyango lwekhemikhali, kunye nezinye iindlela zoomatshini. Phakathi kwabo, ukuqhuma kwesanti kuneempembelelo ezingcono njengoko i-roughens umphezulu we-workpiece, ukwandisa indawo ephezulu kunye nokwenza iigwegwe, ngaloo ndlela iphucula ukubambelela. Emva kwe-sandblasting, i-workpiece surface kufuneka ivuthelwe ngomoya ococekileyo ococekileyo ukususa uthuli, kwaye iplastiki kufuneka ifakwe kwiiyure ezingama-6, ngaphandle koko, umphezulu uya kuba ne-oxidize, echaphazela ukunamathela kwengubo.

uncedo

Ukwaleka ngokuthe ngqo ngeplastiki engumgubo kunezi nzuzo zilandelayo:

- Ingasetyenziswa kunye neerasi ezifumaneka kuphela kwifom yomgubo.

- Ingubo engqindilili inokufumaneka kwisicelo esinye.

- Iimveliso ezinemilo enzima okanye imiphetho ebukhali inokugqithwa kakuhle.

- Uninzi lweeplastiki ezinomgubo zinozinzo oluhle kakhulu lokugcina.

- Akukho zinyibilikisi ezifunekayo, ukwenza inkqubo yokulungiselela izinto zibe lula. Nangona kunjalo, kukwakho nezinye iingxaki okanye imida yokugquma umgubo. Ngokomzekelo, ukuba i-workpiece ifuna ukufudumeza, ubukhulu bayo buya kulinganiselwa. Ngenxa yokuba inkqubo yokwaleka ithatha ixesha, kwii-workpieces ezinkulu, ngelixa ukutshiza kungekagqibi, ezinye iindawo sele zipholile ngaphantsi kobushushu obufunekayo. Ngexesha lenkqubo yokugquma umgubo weplastiki, ilahleko yomgubo inokuba phezulu ukuya kuma-60%, ngoko ke kufuneka iqokelelwe kwaye isetyenziswe kwakhona ukuhlangabezana neemfuno zoqoqosho.

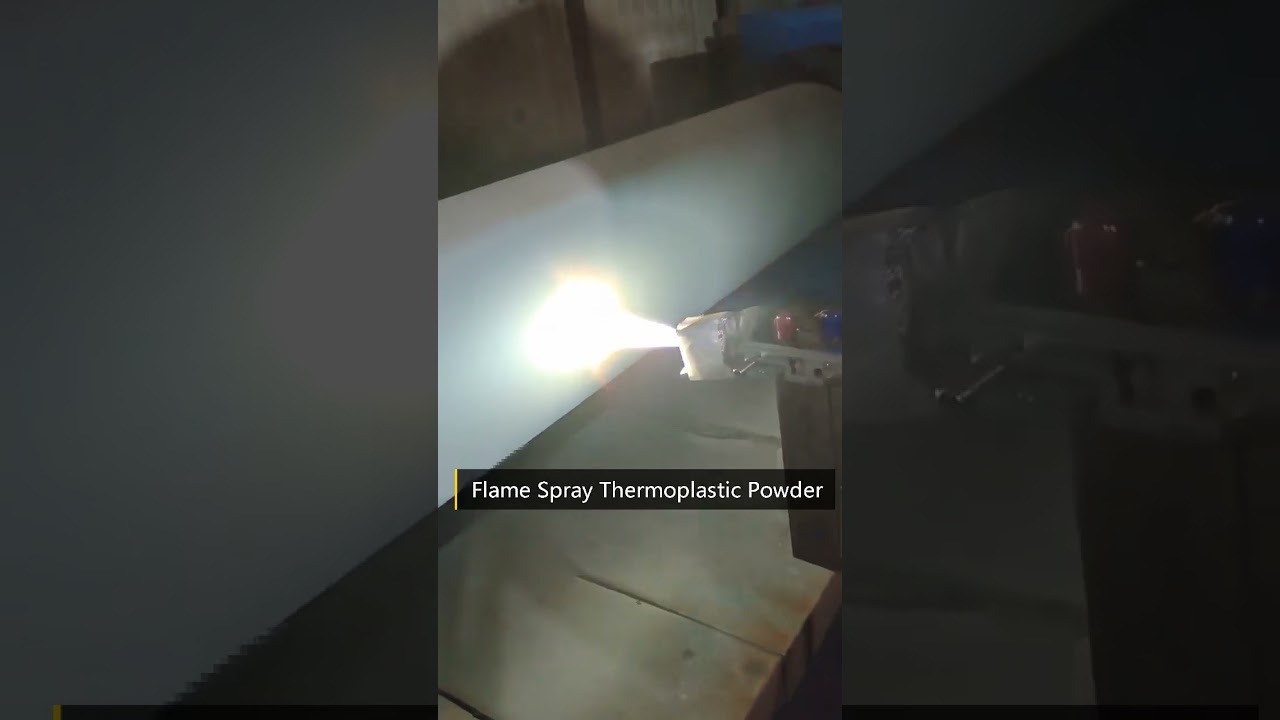

Ukutshiza ilangatye

Idangatye lokutshiza ukutyabeka kweplastiki yentsimbi yinkqubo ebandakanya ukunyibilika okanye ukunyibilika kancinane kweplastiki engumgubo okanye incamagushelo enomlilo ophuma kumpu wokutshiza, emva koko utshize iplastiki enyibilikisiweyo phezu kwento ukuze yenze isaleko seplastiki. Ubunzima bengubo buhlala buphakathi kwe-0.1 kunye ne-0.7 mm. Xa usebenzisa iplastiki engumgubo wokutshiza ilangatye, i-workpiece kufuneka ifudunyezwe. Ukufudumeza kwangaphambili kunokwenziwa kwi-oveni, kwaye ubushushu bangaphambili buyohluka depeukubamba uhlobo lweplastiki etshizwayo.

Iqondo lokushisa lomlilo ngexesha lokutshiza kufuneka lilawulwe ngokungqongqo, njengoko ubushushu obuphezulu bunokutshisa okanye bonakalise iplastiki, ngelixa ubushushu obuphantsi kakhulu bunokuchaphazela ukunamathela. Ngokuqhelekileyo, iqondo lokushisa liphezulu xa utshiza umaleko wokuqala weplastiki, onokuphucula ukunamathela phakathi kwentsimbi kunye neplastiki. Njengoko iileyile ezilandelayo zitshizwa, ubushushu bunokuthotywa kancinci. Umgama phakathi kwesibhamu sokutshiza kunye nomsebenzi kufuneka ube phakathi kwe-100 kunye ne-200 cm. Kwizixhobo zokusebenza ezicwebileyo, i-workpiece kufuneka ibekwe ngokuthe tye kwaye isibhamu sokutshiza kufuneka sihanjiswe ngasemva nangaphambili; kwi-cylindrical okanye i-internal bore workpieces, kufuneka zixhonywe kwi-lathe yokutshiza ngokujikelezayo. Isantya somgca womsebenzi ojikelezayo kufuneka sibe phakathi kwe-20 kunye ne-60 m / min. Emva kokuba ubuninzi obufunekayo bokugquma buphunyeziwe, ukutshiza kufuneka kumiswe kwaye i-workpiece kufuneka iqhubeke ijikeleza kuze kube yilapho iplastiki etyhidiweyo iqina, kwaye kufuneka ipholiswe ngokukhawuleza.

Nangona ukutshiza idangatye kunomgangatho ophantsi wemveliso kwaye kubandakanya ukusetyenziswa kweegesi ezicaphukisayo, kuseyindlela ebalulekileyo yokucubungula kwishishini ngenxa yotyalo-mali oluphantsi lwezixhobo kunye nokusebenza ekugqumeni ingaphakathi lamatanki, izikhongozeli, kunye nezixhobo zokusebenza ezinkulu xa kuthelekiswa nezinye iindlela. .

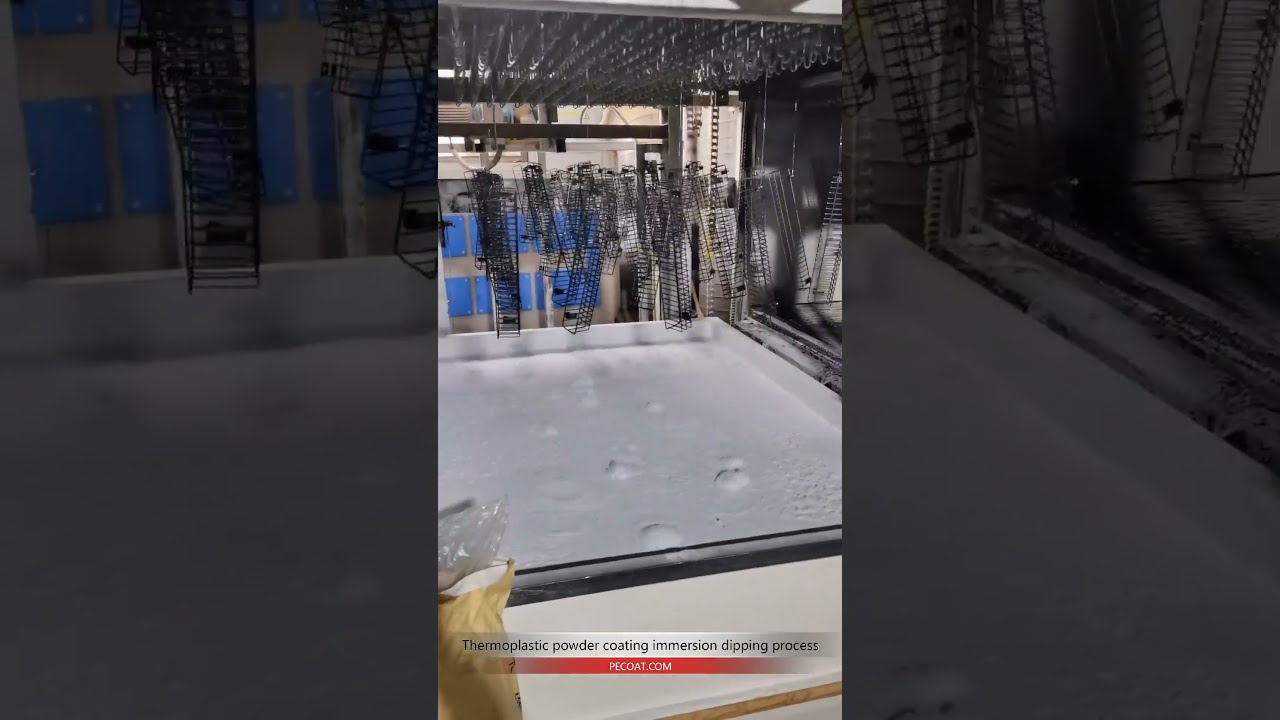

I-Fluidized-bed Dip Coating yePlastiki

Umgaqo osebenzayo we-fluidized bed dip iplastiki yokugquma isinyithi ngolu hlobo lulandelayo: umgubo weplastiki weplastiki ufakwe kwi-cylindrical i-container ene-porous partition phezulu evumela kuphela umoya ukuba udlule, kungekhona umgubo. Xa umoya ocinezelweyo ungena usuka ezantsi kwesikhongozeli, uvuthela umgubo unyuke kwaye uwuxhome kwisingxobo. Ukuba i-workpiece yangaphambili ifakwe kuyo, i-resin powder iya kunyibilika kwaye ibambelele kwi-workpiece, yenza isambatho.

Ubukhulu bengubo efunyenwe kwibhedi emanzi depeIqondo lobushushu, umthamo wobushushu obuthile, i-coefficient yomhlaba, ixesha lokutshiza, kunye nohlobo lweplastiki esetyenziswa xa i-workpiece ingena kwigumbi elixutywe amanzi. Nangona kunjalo, kuphela iqondo lokushisa kunye nexesha lokutshiza le-workpiece liyakwazi ukulawulwa kwinkqubo, kwaye kufuneka zigqitywe ngokuvavanywa kwimveliso.

Ngexesha lokudipha, kuyafuneka ukuba umgubo weplastiki uhambe kakuhle kwaye ulungelelane, ngaphandle kwe-agglomeration, i-vortex flow, okanye ukusasazwa okugqithisileyo kwamasuntswana eplastiki. Amanyathelo angqinelanayo kufuneka athathwe ukuhlangabezana nezi mfuno. Ukongeza isixhobo esishukumisayo kunokunciphisa i-agglomeration kunye nokuhamba kwe-vortex, ngelixa ukongeza inani elincinci le-talcum powder kwipowder yeplastiki kunenzuzo kwi-fluidization, kodwa kunokuchaphazela umgangatho wengubo. Ukuthintela ukusasazwa kweengqungquthela zeplastiki, izinga lokuhamba komoya kunye nokufana kweengqungquthela zeplastiki kufuneka zilawulwe ngokungqongqo. Nangona kunjalo, ukusabalalisa okunye akunakuphepheka, ngoko ke isixhobo sokubuyisela kufuneka sifakwe kwindawo ephezulu yombhede omanzi.

Izinto eziluncedo zokugquma kweplastiki yediphu yebhedi kukukwazi ukugquma izinto zokusebenza ezinokwakheka okuntsonkothileyo, umgangatho ophezulu wokugquma, ukufumana inyameko etyebileyo kwisicelo esinye, ilahleko encinci yentlaka, kunye nendawo yokusebenza ecocekileyo. Ukungalungi bubunzima bokucubungula ii-workpieces ezinkulu.

Electrostatic ukutshiza iplastiki ukutyabeka for metal

Ekutshizweni kwe-electrostatic, i-resin yeplastiki yomgubo wokwaleka igxininiswe kumphezulu we-workpiece ngamandla e-electrostatic, kunokuba inyibilike okanye i-sintering. Umgaqo kukusebenzisa intsimi ye-electrostatic eyenziwe yi-high-voltage ye-electrostatic generator ukuhlawulisa umgubo we-resin otshizwe kumpu wokutshiza ngombane ongatshintshiyo, kunye ne-workpiece esekelwe ibe yi-electrode ephezulu ye-voltage. Ngenxa yoko, umaleko wepowder yeplastiki efanayo ngokukhawuleza ubeka phezu kwendawo yokusebenza. Ngaphambi kokuba umrhumo uchithe, i-powder layer ibambelela ngokuqinileyo. Emva kokufudumeza kunye nokupholisa, i-coating yeplastiki efanayo inokufumaneka.

Ukutshiza ngomgubo we-electrostatic kwaphuhliswa phakathi koo-1960 kwaye kulula ukuzenzela. Ukuba ukutyabeka akufuneki ukuba kube ngqindilili, ukutshiza kwe-electrostatic akufuni ukufudumeza kwangaphambili kwe-workpiece, ngoko ke ingasetyenziselwa izinto ezinobushushu okanye izixhobo zokusebenza ezingafanelanga ukufudumeza. Kananjalo ayifuni isikhongozeli esikhulu sokugcina, esiyimfuneko kwi-fluidized bed spraying. I-powder edlula i-workpiece itsalwa ngasemva kwendawo yokusebenza, ngoko ke inani le-overspray lincinci kakhulu kunezinye iindlela zokutshiza, kwaye yonke i-workpiece inokugqunywa ngokutshiza kwelinye icala. Nangona kunjalo, ii-workpieces ezinkulu zisafuna ukutshizwa macala omabini.

Izixhobo zokusebenza ezinamacandelwana ahlukeneyo zingabangela ubunzima bokufudumeza okulandelayo. Ukuba ulwahlulo kwi-cross-section likhulu kakhulu, inxalenye ethe tye yengubo ayinakufikelela kwiqondo lokushisa elinyibilikayo, ngelixa i-thinner part ingaba sele inyibilikile okanye iyancipha. Kule meko, ukuzinza kwe-thermal ye-resin kubalulekile.

Izixhobo ezineekona zangaphakathi ezicocekileyo kunye nemingxuma enzulu azigqunywanga ngokulula ngokutshiza nge-electrostatic kuba ezi ndawo zine-electrostatic shielding kunye ne-r.epel i powder, ukuthintela ukugquma ekungeneni kwiikona okanye emigodini ngaphandle kokuba isibhamu sokutshiza singafakwa kuzo. Ukongeza, ukutshiza kwe-electrostatic kufuna amasuntswana acolekileyo kuba amasuntswana amakhulu kunokwenzeka ukuba ahlukane nomsebenzi, kwaye amasuntswana acolekileyo kune-150 mesh asebenza ngakumbi kwisenzo se-electrostatic.

Indlela yokwaleka yokunyibilika eshushu

Umgaqo osebenzayo wendlela yokutshisa i-melt melt ukutshiza i-powder yokugqoka iplastiki kwi-workpiece eshushu ngaphambili usebenzisa umpu wokutshiza. Iplastiki iyanyibilika ngokusebenzisa ubushushu bomsebenzi, kwaye emva kokupholisa, iplastiki yokwambathisa ingafakwa kwindawo yokusebenza. Ukuba kuyimfuneko, unyango lwe-post-heating luyafuneka.

Isitshixo sokulawula inkqubo yokwaleka okutshisayo yi-preheating ye-workpiece. Xa ukushisa kwangaphambi kokushisa kuphezulu kakhulu, kunokubangela i-oxidation enzima yobuso besinyithi, ukunciphisa ukunamathela kwengubo, kwaye kunokubangela ukubola kwe-resin kunye ne-foaming okanye i-discoloration of the coating. Xa ubushushu bokufudumala buphantsi kakhulu, i-resin ayinakuhamba kakuhle, okwenza kube nzima ukufumana i-coating efanayo. Rhoqo, isicelo esinye sokutshiza sendlela yokwaleka eshushu yokunyibilika ayinakufezekisa ubukhulu obufunwayo, ngoko ke kuyafuneka izicelo zokutshiza ezininzi. Emva kwesicelo ngasinye sokutshiza, unyango lokufudumala luyimfuneko ukuba lunyibilike ngokupheleleyo kwaye lukhanyise isambatho ngaphambi kokufaka umgca wesibini. Oku akuqinisekisi kuphela i-uniform kunye ne-coating egudileyo kodwa iphucula kakhulu amandla omatshini. Iqondo lokushisa elicetyiswayo lokufudumeza kwi-polyethylene ephezulu lijikeleze i-170 ° C, kunye ne-polyether ye-chlorinated, ijikeleze i-200 ° C, kunye nexesha elicetyiswayo le-1 iyure.

Indlela yokwaleka eshushu enyibilikayo ivelisa umgangatho ophezulu, obukekayo, obotshelelwe ngokuqinileyo kunye nelahleko encinci ye-resin. Kulula ukuyilawula, inevumba elincinane, kwaye umpu wokutshiza osetyenziswayo uyakwenza.

Ezinye iindlela ezikhoyo zokugquma ngeplastiki yentsimbi

1. Ukutshiza: Gcwalisa ukunqunyanyiswa kwindawo yokugcina imipu yokutshiza kwaye usebenzise umoya ocinezelekileyo ngoxinzelelo lwegeyiji engadlulanga kwi-0.1 MPa ukutshiza ngokulinganayo isambatho phezu komphezulu wesixhobo sokusebenza. Ukunciphisa ilahleko yokumiswa, uxinzelelo lomoya kufuneka lugcinwe lusezantsi kangangoko. Umgama phakathi kwendawo yokusebenza kunye ne-nozzle kufuneka ugcinwe kwi-10-20 cm, kwaye indawo yokutshiza kufuneka igcinwe i-perpendicular ukuya kwicala lokuhamba kwezinto.

2. Ukuntywiliselwa: Gxininisa i-workpiece kwi-suspension imizuzwana embalwa, uze uyisuse. Ngeli xesha, umaleko wokunqunyanyiswa uya kubambelela kumphezulu womsebenzi, kwaye ulwelo olugqithisileyo lunokuhamba ngokwemvelo. Le ndlela ifanelekile kwii-workpieces ezincinci ezifuna ukugquma okupheleleyo kumphezulu wangaphandle.

3. Ukuxubha: Ukuxubha kubandakanya ukusebenzisa ibrashi yepeyinti okanye ibrashi yokufaka ukumiswa phezu kwendawo yokusebenza, ukudala isambatho. Ukuxubha kukulungele ukugquma kwendawo okanye ukugquma kwicala elinye kwindawo emxinwa. Nangona kunjalo, kunqabile ukuba isetyenziswe ngenxa yesiphumo esincinci esigudileyo kunye nomphezulu emva kokuba i-coating isomisiwe, kunye nokulinganiselwa kobunzima bomaleko ngamnye.

4. Ukugalela: Galela ukumiswa kwi-workpiece ejikelezayo ejikelezayo, uqinisekise ukuba indawo yangaphakathi ihlanganiswe ngokupheleleyo ngokumiswa. Emva koko, uthele ulwelo olugqithisileyo ukwenza isambatho. Le ndlela ilungele ukugquma ii-reactors ezincinci, imibhobho, iingqiniba, iivalvu, ii-casings zempompo, ii-tee, kunye nezinye izixhobo zokusebenza ezifanayo.

Ndikhangela izinto zokuhombisa ze-thermoplastic zocingo lwentsimbi

Le ndawo ye-Intanethi ndiphefumla kuyo, uyilo oluhle kakhulu kunye nomxholo ogqibeleleyo.

Ndicinga ukuba olu lolunye lolwazi olubaluleke kakhulu kum. Kwaye ndiyavuya ukufunda inqaku lakho. Kodwa ndifuna ukuthetha ngezinto ezimbalwa eziqhelekileyo, incasa yesayithi igqibelele, amanqaku eneneni alungile: D. Umsebenzi olungileyo, cheers