Ipeyinti yePowder ye-Thermoplastic-uMboneleli, uPhuhliso, iiPros and Cons

Umthengisi

iTshayina PECOAT® ekhethekileyo kwimveliso kunye nokuthunyelwa kwamanye amazwe ipeyinti yomgubo we-thermoplastic, imveliso ine polyethylene powder ipeyinti, pvc powder ipeyinti, umgubo wenayiloni ipeyinti, kwaye ibhedi emanzi izixhobo zokudipha.

Imbali yoPhuhliso lwePaint ye-Thermoplastic Powder

Ukusukela kwintlekele ye-oyile ngeminyaka yoo-1970s, umgubo wokugquma ukhule ngokukhawuleza ngenxa yogcino lwemithombo yawo, ubuhlobo bendalo, kunye nokufaneleka kwemveliso ezenzekelayo. Ipeyinti yomgubo we-Thermoplastic (ekwabizwa ngokuba yi-thermoplastic powder coating), enye yeentlobo ezimbini eziphambili zepeyinti yomgubo, yaqala ukuvela ekupheleni kwe-1930s.

Kwiminyaka ye-1940, kunye nophuhliso lweshishini le-petrochemical kunye namanye amashishini, ukuveliswa kwee-resin ezifana ne-polyethylene, i-polyvinyl chloride, kunye ne-polyamide resin yanda ngokukhawuleza, okukhokelela kuphando lwepeyinti ye-thermoplastic powder. Ekuqaleni, abantu babefuna ukusebenzisa i-polyethylene ukuchasana kweekhemikhali ukuze bayifake kwi-coating yentsimbi. Nangona kunjalo, i-polyethylene ayinyibiliki kwi-solvents kwaye ayinakwenziwa kwiingubo ezisekelwe kwi-solvent, kwaye i-adhesives efanelekileyo ayifumanekanga ukunamathela ishidi le-polyethylene eludongeni lwangaphakathi lwesinyithi. Ngoko ke, ukutshiza idangatye kwakusetyenziselwa ukunyibilika kunye nokugquma i-polyethylene powder kwindawo yesinyithi, ngaloo ndlela kuvula ukuqala kwepeyinti ye-thermoplastic powder.

Fluidized ebhedini ukutyabeka, okwangoku iyona ndlela isetyenziswa kakhulu kwaye ixhaphake indlela yokwaleka kwipeyinti ye-thermoplastic powder, yaqala ngendlela yokufafaza ngokuthe ngqo ngo-1950. Kule ndlela, i-resin powder ifafazwe ngokulinganayo kwindawo eshushu ye-workpiece ukuze yenze i-coating. Ukuze wenze indlela yokutshiza ibe ngokuzenzekelayo, indlela yokugquma ibhedi egudileyo yavavanywa ngempumelelo eJamani ngowe-1952. Indlela yokugquma ibhedi esebenzisa umoya okanye irhasi engasebenziyo evuthelwa kwipleyiti evuzayo ephantsi kwebhedi eyenza usasazo olufanayo. Ukuhamba komoya osasazekileyo, okwenza umgubo kumandlalo omanzi aqukuqelele kwindawo ekufutshane nolwelo, ukuze i-workpiece isasazwe ngokulinganayo kumphezulu womsebenzi kwaye ifumane indawo egudileyo necaba.

Iintlobo kunye neeNgxaki kunye neeNgcaciso zePaint ye-Thermoplastic Powder

Okwangoku, ipeyinti yomgubo we-thermoplastic ibandakanya iintlobo ezahlukeneyo ezifana ne-polyethylene /polypropylene i-polyvinyl chloride powder coatings, i-polyvinyl chloride powder coatings, i-nylon powder coatings, i-polytetrafluoroethylene powder coatings, kunye ne-thermoplastic polyester powder coatings. Ziye zasetyenziswa ngokubanzi ekukhuseleni izithuthi, imibhobho yokunqanda ukubola, kunye nezinto ezahlukeneyo zasekhaya.

Polyethylene (PE) kunye ne-polypropylene (PP) i-powder coating

I-Polyethylene kunye ne-polypropylene zaziphakathi kwezinto zokuqala ezisetyenziswe kwipeyinti yomgubo we-thermoplastic kwaye yayizezona zimbini zibalulekileyo. iipolymers thermoplastic kwinkulungwane edlulileyo. Okwangoku, zombini i-polyethylene ephezulu kunye ne-low-density isetyenziswe kwintsimi ye-thermoplastic. I-polyethylene ephezulu yoxinaniso idla ngokusetyenziswa kwintsimi yezoshishino, ngelixa i-polyethylene ephantsi-ephantsi isetyenziswa kwintsimi yoluntu.

Njengoko ikhonkco lemolekyuli ye-polyethylene kunye ne-polypropylene yibhondi ye-carbon-carbon, zombini ineempawu ezingezizo ze-olefins, ngoko ke i-polyethylene kunye ne-polypropylene powder coatings zinokuchasana kakuhle kweekhemikhali kwaye zisetyenziswa ngokubanzi kwintsimi yokuchasana nokubola. Zisetyenziselwa ukukhusela, ukugcina, kunye nezikhongozelo zokuthutha, imibhobho, kunye nemibhobho yeoli yeekhemikhali kunye nezixhobo zokulungisa imichiza. Njengezinto ezingasebenziyo, olu hlobo lwepeyinti yepowder lunokubambelela kakubi kwi-substrate kwaye lufuna unyango olungqongqo lwe-substrate, okanye ukusetyenziswa kwe-primer okanye ukuguqulwa kwe-polyethylene nezinye izinto.

uncedo

I-polyethylene resin yeyona isetyenziswa kakhulu kwaye iveliswa ipeyinti yomgubo we-thermoplastic.

Inezi zinto zilandelayo:

- Ukuchasana kwamanzi okugqwesileyo, ukuxhathisa kwe-asidi kunye ne-alkali, kunye nokuchasana kweekhemikhali;

- Ukufakwa kakuhle kombane kunye neempawu zokufakelwa kwe-thermal;

- Amandla okuqina agqwesileyo, ukuguquguquka, kunye nokumelana nempembelelo;

- Ukumelana kakuhle nobushushu obuphantsi, kunokugcina iiyure ezingama-400 ngaphandle kokuqhekeka kwi -40 ℃;

- Ixabiso elihambelanayo lemathiriyeli ekrwada liphantsi, alinabungozi kwaye lihambelana nokusingqongileyo.

Ngengozi

Nangona kunjalo, ngenxa yeepropathi ze-substrate polyethylene, ipeyinti yomgubo we-polyethylene nayo inemiqobo engenakuthintelwa:

- Ukuqina, ukuxhathisa ukuguga, kunye namandla omatshini wokugquma awona mahle kakhulu;

- Ukubambelela kwengubo kubi kwaye i-substrate kufuneka iphathwe ngokungqongqo;

- Ukuchasana nemozulu embi, kukulungele ukucinezeleka kokuqhekeka emva kokuvezwa kwimitha ye-ultraviolet;

- Ukumelana nobushushu obuphantsi kunye nokumelana nobushushu obufumileyo.

Polyvinyl chloride (PVC) ukugquma umgubo

Polyvinyl chloride (PVC) i-polymer e-amorphous equkethe inani elincinci leekristale ezingaphelelanga. Uninzi PVC iimveliso ze-resin zinobunzima bemolekyuli phakathi kwe-50,000 kunye ne-120,000. Nangona ubunzima obuphezulu bemolekyuli PVC iirasi zineempawu ezingcono zomzimba, ubunzima obuphantsi bemolekyuli PVC iireyini ezine-viscosity encibilikayo esezantsi kunye nobushushu obuthambisayo zifaneleke ngakumbi njengezixhobo zepeyinti yomgubo we-thermoplastic.

PVC yona ngokwayo iyinto eqinileyo kwaye ayinakusetyenziswa njengomgubo wepeyinti yodwa. Xa usenza iingubo, inani elithile leplastiki kufuneka lifakwe ukulungelelanisa ukuguquguquka kwe PVC. Kwangaxeshanye, ukongeza iiplasticizers kukwanciphisa ukomelela kwesixhobo, imodulus, kunye nokuqina. Ukukhetha uhlobo olufanelekileyo kunye nobungakanani beplasticizer kunokufezekisa ibhalansi oyifunayo phakathi kokuguquguquka kwezinto kunye nobunzima.

Ngokupheleleyo PVC ifomula yepeyinti yomgubo, izinzisi nazo ziyinxalenye ebalulekileyo. Ukusombulula uzinzo thermal of PVC, iityuwa ezixutywe nge-calcium kunye ne-zinc ngokuzinza kakuhle kwe-thermal, i-barium kunye cadiisepha ze-mium, i-mercaptan tin, i-dibutyltin derivatives, i-epoxy compounds, njl. Nangona i-lead stabilizers inozinzo oluhle kakhulu lwe-thermal, baye bakhutshwa ngaphandle kwemarike ngenxa yezizathu zokusingqongileyo.

Okwangoku, iimveliso ezisetyenziswa kakhulu PVC ipeyinti yomgubo zizinto ezahlukeneyo zombane zasekhaya kunye neerakhi zokuhlamba izitya. PVC iimveliso zinokuxhathisa okulungileyo kokuhlamba kunye nokuchasana nokungcoliswa kokutya. Ziyakwazi nokunciphisa ingxolo yeeracks zesitya. Dish racks ziqatywe PVC iimveliso aziyi kwenza ngxolo xa ubeka i-tableware. PVC umgubo wokwaleka unokufakwa ngolwakhiwo lwebhedi enolwelo okanye ukutshiza nge-electrostatic, kodwa zifuna ubungakanani bamasuntswana omgubo. Kufuneka kwakhona kuqatshelwe ukuba PVC ipeyinti yomgubo ikhupha ivumba elibi ngexesha lokuntywiliselwa kwaye iyingozi kumzimba womntu. Ukusetyenziswa kwabo sele kuqalile ukuthintelwa kumazwe angaphandle.

uncedo

Uncedo lwepeyinti yepolyvinyl chloride yomgubo zezi:

- Amaxabiso aphantsi ezinto eziphathekayo;

- Ukumelana nokungcoliseka okulungileyo, ukuxhathisa ukuhlamba, kunye nokuxhathisa umhlwa;

- Amandla omatshini aphezulu kunye nokusebenza kakuhle kokufakelwa kombane.

Ngengozi

Izinto ezingeloncedo ngepeyinti yomgubo wepolyvinyl chloride zezi:

- Umahluko weqondo lobushushu phakathi kokunyibilika kobushushu kunye nobushushu bokubola kwe PVC intlaka incinci. Ngethuba lenkqubo yokugubungela, ukushisa kufuneka kulawulwe ngokungqongqo ukuthintela ukubola.

- Ukwaleka akuxhathisi kwi-hydrocarbons enevumba elimnandi, ii-esters, iiketones, kunye nezinyibilikisi eziklorini, njl.

Polyamide (nayiloni) yokwaleka umgubo

I-Polyamide resin, eyaziwa ngokuba yinayiloni, yintlaka ye-thermoplastic esetyenziswa ngokubanzi. Inayiloni ineempawu ezintle ezibanzi, ubunzima obuphezulu, kunye nokumelana nokunxiba okubalaseleyo. I-coefficients eguquguqukayo kunye ne-static ye-friction ye-nylon yokwambathisa incinci, kwaye ine-lubricity. Ke ngoko, zisetyenziswa kwiibheringi zoomatshini belaphu, iigiya, iivalvu, njl njl. Iingubo zomgubo zenayiloni zine-lubricity elungileyo, ingxolo ephantsi, ukuguquguquka okuhle, ukunamathela okugqwesileyo, ukuxhathisa imichiza, kunye nokumelana ne-solvent. Zingasetyenziswa njengeyona ndlela ifanelekileyo yokunxiba kunye neyokuthambisa ukuze ithathe indawo yobhedu, ialuminium, cadi-mium, intsimbi, njl njl. Ubuninzi befilimu yokugquma i-nylon yi-1/7 kuphela yobhedu, kodwa ukuxhathisa ukunxiba kuphindwe kasibhozo kunobhedu.

Iingubo zomgubo zenayiloni azinatyhefu, azinavumba kwaye azinancasa. Ngokudityaniswa nenyani yokuba azichaphazeleki kuhlaselo lomngundo okanye ukukhuthaza ukukhula kwebhaktiriya, zifakwa ngempumelelo kwishishini lokulungisa ukutya ukuze zigqume iinxalenye zoomatshini kunye neenkqubo zemibhobho okanye ukugquma imiphezulu edibana ngqo nokutya. Ngenxa yokunganyangeki kwayo okugqwesileyo kwamanzi kunye netyuwa, ikwasetyenziswa ngokuqhelekileyo ukugquma iindawo zomatshini wokuhlamba, njl.

Indawo ebalulekileyo yesicelo se-nylon powder yokugqoka i-nylon powder kukugqoka iintlobo ezahlukeneyo zokubamba, kungekhona nje ngokuba zineempawu ezibalulekileyo ezifana nokuxhatshazwa kokugqoka kunye nokuchasana nokuqala, kodwa nangenxa yokuba i-conductivity ephantsi ye-thermal yenza ukuba izibambo zizive zithambile. Oku kwenza ezi zixhobo zifaneleke kakhulu kwizibambo zesixhobo sokugquma, izibambo zocango, kunye namavili okuqhuba.

Xa kuthelekiswa nezinye iingubo zokugquma, iifilimu zokugquma inayiloni zinokumelana neekhemikhali ezingalunganga kwaye azifanelekanga ukuba zisetyenziswe kwiimeko zeekhemikhali ezinjengeeasidi kunye nealkali. Ke ngoko, ezinye iireyini ze-epoxy zongezwa ngokubanzi njengeemodyuli, ezingenakuphucula kuphela ukuxhathisa kokubola kweengubo zenayiloni kodwa zikwaphucula amandla okubopha phakathi kwefilimu yokugquma kunye nenxalenye yentsimbi. Umgubo wenayiloni unomlinganiselo ophezulu wokufunxa amanzi kwaye uchaphazeleka kukufuma ngexesha lokwakhiwa nokugcinwa. Ngoko ke, kufuneka igcinwe phantsi kweemeko ezivaliweyo kwaye akufanele isetyenziswe ixesha elide phantsi kweemeko ezimanzi kunye nezishushu. Enye inkalo yokuqaphela kukuba ixesha leplastiki ye-nylon powder lifutshane, kwaye ifilimu yokugqoka engadingi i-plasticizing inokufezekisa umphumo oyifunayo, oyinto ekhethekileyo ye-nylon powder.

Ipeyinti yepolyvinylidene fluoride (PVDF) powder

Eyona nto imele i-coatre-resistant weather in thermoplastic powder paint is polyvinylidene fluoride (PVDF) powder coating. Njengoyena ummeli we-ethylene polymer ukumelana nemozulu, i-PVDF inobuchwephesha obulungileyo kunye nokuchasana kwempembelelo, ukuxhathisa okugqwesileyo, ukuguquguquka okugqwesileyo kunye nobunzima, kwaye inokumelana neekhemikhali ezininzi ezinobungozi ezifana ne-asidi, i-alkali, kunye nee-oxidants ezomeleleyo. Ngaphezu koko, ayinyibiliki kwiikhemikhali ezinyibilikayo ezisetyenziswa ngokuqhelekileyo kwishishini lezogquma, ezibangelwa kwiibhondi ze-FC eziqulethwe kwi-PVDF. Kwangaxeshanye, i-PVDF ikwahlangabezana neemfuno ze-FDA kwaye ingasetyenziswa ekwenzeni ukutya kwaye inokudibana nokutya.

Ngenxa ye-viscosity ephezulu yokunyibilika kwayo, i-PVDF ithanda ukuba nemingxunya kunye nokunamathelwa kwentsimbi emdaka kwifilimi ebhityileyo, kwaye ixabiso lezinto ezibonakalayo liphezulu kakhulu. Ke ngoko, kwiimeko ezininzi, ayisetyenziswanga njengesiseko sodwa sezinto zokugquma umgubo. Ngokuqhelekileyo, malunga ne-30% ye-acrylic resin yongezwa ukuphucula ezi zakhiwo. Ukuba umxholo we-acrylic resin uphezulu kakhulu, uya kuchaphazela ukuchasana kwemozulu yefilimu yokugqoka.

Iglosi yefilimu yokugquma yePVDF isezantsi noko, ijikeleze i-30±5%, nto leyo ethintela ukusetyenziswa kwayo ekuhombiseni umphezulu. Okwangoku, isetyenziswa ikakhulu njengokwaleka kwesakhiwo kwizakhiwo ezikhulu, isetyenziswa kwiipaneli zophahla, iindonga, kunye nezakhelo zefestile zealuminium ezikhutshiweyo, ezinokumelana nemozulu entle kakhulu.

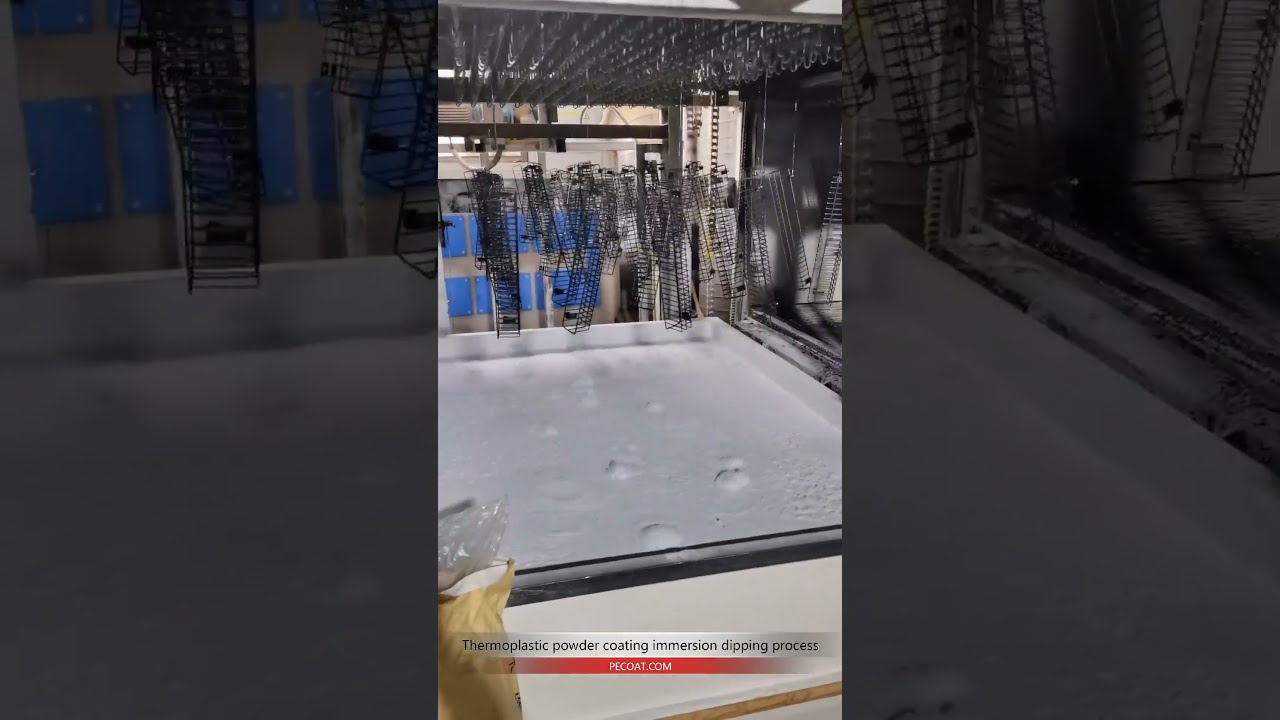

Sebenzisa iVidiyo

Enkosi ngoncedo lwakho kunye nokubhala le post malunga nepeyinti yomgubo. Kube kuhle.