I-Plastic Coating For Metal

Ukufakwa kwepulasitiki kwenqubo yensimbi ukufaka ungqimba lwepulasitiki ebusweni bezingxenye zensimbi, ezivumela ukuthi zigcine izici zangempela zensimbi ngenkathi futhi zihlinzeka ngezakhiwo ezithile zepulasitiki, njengokumelana nokugqwala, ukumelana nokugqokwa, ukwahlukanisa ugesi, kanye nokuzimela. -ukugcoba. Le nqubo ibaluleke kakhulu ekwandiseni uhla lokusetshenziswa kwemikhiqizo kanye nokuthuthukisa ukubaluleka kwayo kwezomnotho.

Izindlela zokumboza ipulasitiki ngensimbi

Ziningi izindlela zokumboza ngepulasitiki, okuhlanganisa ukufutha amalangabi, umbhede omanzi ukufutha, impushana yokufutha i-electrostatic, i-hot melt coating, kanye ne-suspension coating. Kukhona futhi izinhlobo eziningi zepulasitiki ezingasetshenziselwa ukunamathela, nge PVC, PE, kanye ne-PA okuyizona ezisetshenziswa kakhulu. Ipulasitiki esetshenziselwa ukumboza kufanele ibe yimpushana, ibe ne-fineness ye-80-120 mesh.

Ngemuva kokumboza, kungcono ukupholisa ngokushesha i-workpiece ngokuyicwilisa emanzini abandayo. Ukupholisa okusheshayo kunganciphisa ukucwebezela kwe-coating yepulasitiki, kwandise okuqukethwe kwamanzi, kuthuthukise ukuqina nokukhanya kwendawo yokumboza, kukhuphule ukunamathela, futhi kunqobe ukugoqa okubangelwa ukucindezeleka kwangaphakathi.

Ukuze uthuthukise ukunamathela phakathi kokugqoka kanye nesisekelo sensimbi, ubuso be-workpiece kufanele bungabi nothuli futhi bome, ngaphandle kokugqwala namafutha ngaphambi kokugqoka. Ezimweni eziningi, i-workpiece idinga ukwelashwa okungaphezulu. Izindlela zokwelapha zihlanganisa ukuqhunyiswa kwesihlabathi, ukwelashwa ngamakhemikhali, nezinye izindlela zemishini. Phakathi kwazo, i-sandblasting inemiphumela engcono kakhulu njengoba ihlukumeza indawo yokusebenza, ikhulisa indawo engaphezulu futhi yenza izingwegwe, ngaleyo ndlela ithuthukise ukunamathela. Ngemuva kwe-sandblasting, indawo yokusebenzela kufanele iqhunyiswe ngomoya ohlanzekile ocindezelwe ukuze kukhishwe uthuli, futhi ipulasitiki kufanele iboshwe kungakapheli amahora angu-6, ngaphandle kwalokho, ubuso buzokhipha i-oxidize, okuthinta ukunamathela kokugqoka.

Advantage

Ukugqoka okuqondile ngepulasitiki eyimpuphu kunezinzuzo ezilandelayo:

- Ingasetshenziswa nama-resin atholakala kuphela ngesimo sempushana.

- I-coating ewugqinsi ingatholakala kuhlelo lokusebenza olulodwa.

- Imikhiqizo enezimo eziyinkimbinkimbi noma imiphetho ebukhali ingafakwa kahle.

- Amapulasitiki amaningi ayimpuphu anokusimama okuhle kakhulu kokugcina.

- Awekho ama-solvents adingekayo, okwenza inqubo yokulungiselela impahla ibe lula. Kodwa-ke, kukhona futhi ezinye izithiyo noma ukulinganiselwa enamathela powder. Isibonelo, uma i-workpiece idinga ukushiswa, ubukhulu bayo buzonqunywa. Ngenxa yokuthi inqubo yokumboza ithatha isikhathi, kuma-workpieces amakhulu, kuyilapho ukufafaza kungakaqedwa, ezinye izindawo sezivele zipholile ngaphansi kwezinga lokushisa elidingekayo. Ngesikhathi senqubo yokumboza ngepulasitiki, ukulahleka kwempushana kungase kufinyelele ku-60%, ngakho-ke kufanele kuqoqwe futhi kusetshenziswe kabusha ukuze kuhlangatshezwane nezidingo zezomnotho.

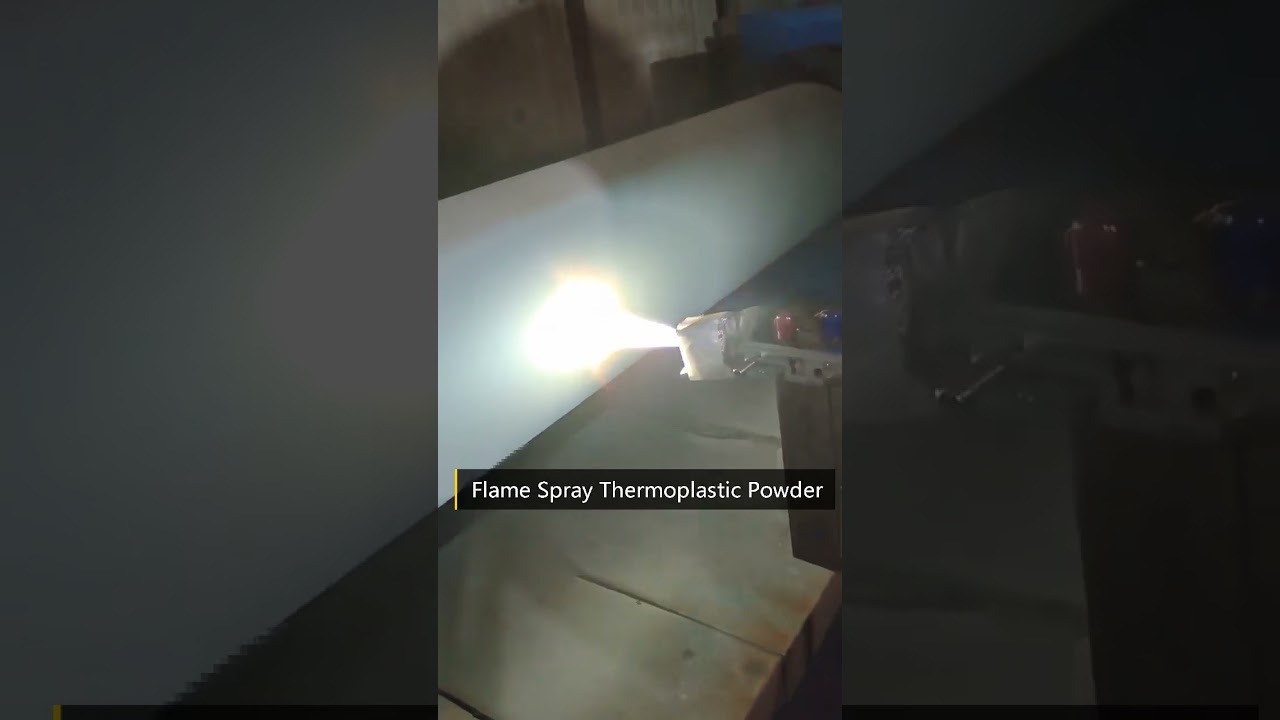

Ukufutha Kwamalangabi

I-Flame spraying coating for metal iyinqubo ehlanganisa ukuncibilika noma ukuncibilika ingxenye yepulasitiki eyimpuphu noma enamathiselwe nelangabi eliphuma kusibhamu sokufutha, bese ufafaza ipulasitiki encibilikisiwe phezu kwento ukuze kwakheke ipulasitiki. Ubukhulu be-coating ngokuvamile buphakathi kuka-0.1 no-0.7 mm. Uma usebenzisa ipulasitiki eyimpuphu yokufafaza amalangabi, umsebenzi wokusebenzela kufanele ushiswe ngaphambili. Ukushisa kuqala kungenziwa kuhhavini, futhi izinga lokushisa langaphambi kokushisa liyahlukahluka depeukugxila ohlotsheni lwepulasitiki olufuthwayo.

Izinga lokushisa lomlilo ngesikhathi sokufafaza kufanele lilawulwe ngokuqinile, njengoba izinga lokushisa eliphakeme kakhulu lingashisa noma kulimaze ipulasitiki, kuyilapho izinga lokushisa eliphansi kakhulu lingathinta ukunamathela. Ngokuvamile, izinga lokushisa liphakeme kakhulu lapho ufafaza ungqimba lokuqala lwepulasitiki, olungathuthukisa ukunamathela phakathi kwensimbi nepulasitiki. Njengoba izingqimba ezilandelayo zifuthwa, izinga lokushisa lingehliswa kancane. Ibanga phakathi kwesibhamu se-spray kanye ne-workpiece kufanele ibe phakathi kuka-100 no-200 cm. Kuma-workpieces ayisicaba, i-workpiece kufanele ibekwe ngokuvundlile futhi isibhamu se-spray kufanele sihanjiswe emuva naphambili; kuma-workpieces angama-cylindrical noma angaphakathi, kufanele afakwe ku-lathe ukuze afuthwe ngokujikelezayo. Isivinini somugqa womsebenzi ojikelezayo kufanele sibe phakathi kuka-20 no-60 m/min. Ngemuva kokuthi ugqinsi oludingekayo lwe-coating selufinyelelwe, ukufafaza kufanele kumiswe futhi i-workpiece kufanele iqhubeke nokujikeleza kuze kube yilapho ipulasitiki encibilikisiwe iqina, bese kufanele ipholiswe ngokushesha.

Nakuba ukufutha amalangabi kunokukhiqiza kahle okuphansi futhi kuhilela ukusetshenziswa kwamagesi acasulayo, kuseyindlela ebalulekile yokucubungula embonini ngenxa yokutshalwa kwezimali kwemishini ephansi nokusebenza kahle ekuhlanganiseni ingaphakathi lamathangi, iziqukathi, kanye nezingxenye zokusebenza ezinkulu uma kuqhathaniswa nezinye izindlela. .

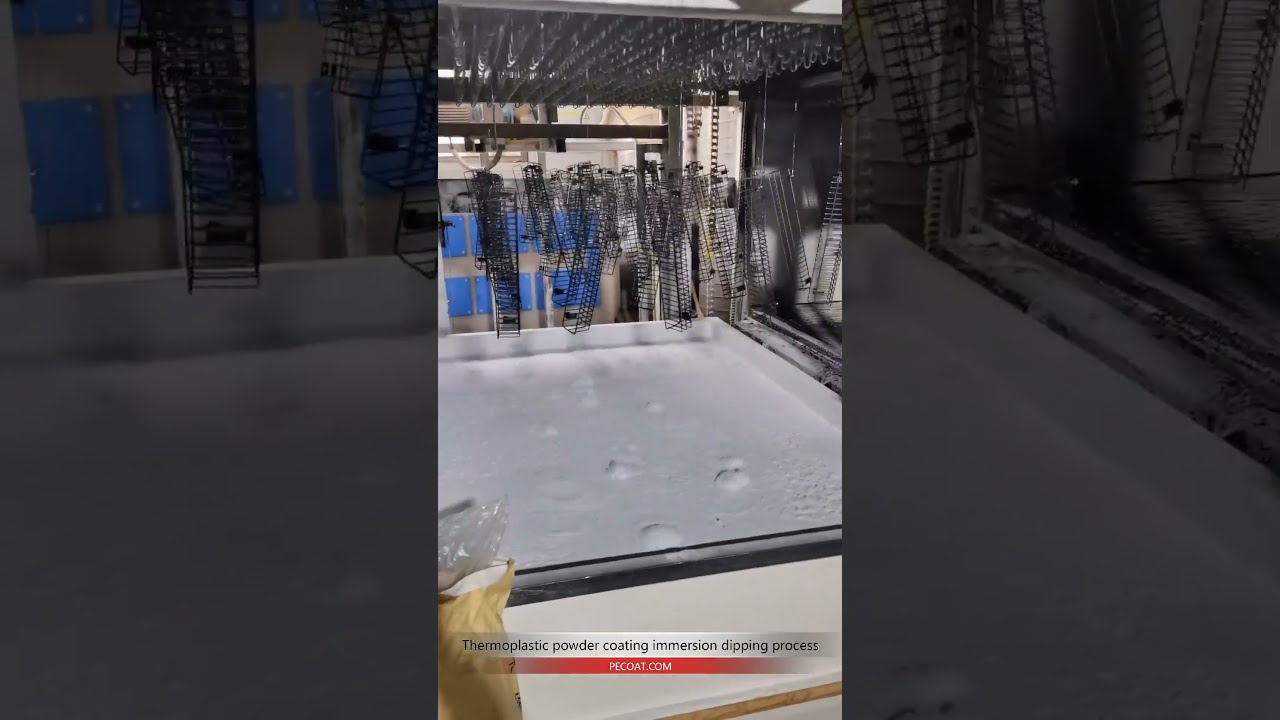

I-Fluidized-bed Dip Plastic Coating

Umgomo wokusebenza we-fluidized bed dip plastic coating for metal umi kanje: i-plastic coating powder ifakwa esitsheni esiyicylindrical esine-porous partition phezulu evumela umoya kuphela ukuba udlule, hhayi impushana. Uma umoya ocindezelwe ungena usuka phansi kwesiqukathi, ufutha impushana uyiphakamise bese uyimisa esitsheni. Uma i-workpiece eshisiwe igxiliwe kuyo, i-resin powder izoncibilika futhi inamathele ku-workpiece, yakha i-coating.

Ugqinsi lwe-coating etholakala embhedeni omanzi depeIfinyelela ezingeni lokushisa, umthamo wokushisa othize, i-surface coefficient, isikhathi sokufutha, kanye nohlobo lwepulasitiki olusetshenziswa lapho ucezu lokusebenza lungena egumbini elixutshwe amanzi. Kodwa-ke, izinga lokushisa kuphela nesikhathi sokufutha se-workpiece esingalawulwa kule nqubo, futhi zidinga ukunqunywa ukuhlolwa ekukhiqizeni.

Ngesikhathi sokucwiliswa, kuyadingeka ukuthi impushana yepulasitiki igeleze ngokushelela nangokulinganayo, ngaphandle kwe-agglomeration, ukugeleza kwe-vortex, noma ukuhlakazeka ngokweqile kwezinhlayiya zepulasitiki. Izinyathelo ezihambelanayo kufanele zithathwe ukuhlangabezana nalezi zidingo. Ukwengeza idivayisi eshukumisayo kunganciphisa ukugeleza kwe-agglomeration nokugeleza kwe-vortex, kuyilapho ukwengeza inani elincane le-talcum powder ku-powder epulasitiki kunenzuzo yokuguquguquka, kodwa kungase kuthinte ikhwalithi yokugqoka. Ukuze uvimbele ukuhlakazeka kwezinhlayiya zepulasitiki, izinga lokugeleza komoya kanye nokufana kwezinhlayiya zepulasitiki zempuphu kufanele kulawulwe ngokuqinile. Kodwa-ke, okunye ukuhlakazeka akunakugwenywa, ngakho-ke idivayisi yokutakula kufanele ifakwe engxenyeni engenhla yombhede omanzi.

Izinzuzo ze-fluidized bed dip coating yepulasitiki yikhono lokumboza izingcezu zokusebenza ezinomumo oyinkimbinkimbi, ikhwalithi ephezulu yokunamathela, ukuthola ukunamathela okushubile ohlelweni olulodwa, ukulahleka okuncane kwe-resin, nendawo yokusebenza ehlanzekile. Okubi wubunzima bokucubungula ama-workpieces amakhulu.

Electrostatic spraying plastic enamathela for metal

Ekufuthweni kwe-electrostatic, i-resin enamathela impushana yepulasitiki igxiliswa phezu kwendawo yokusebenza ngamandla e-electrostatic, kunokuncibilika noma ukucwiliswa. Isimiso siwukusebenzisa inkambu ye-electrostatic eyakhiwe i-high-voltage electrostatic generator ukushaja impushana ye-resin efuthwe ngesibhamu sokufutha ngogesi ongashintshi, futhi i-workpiece esekelwe phansi iba i-electrode ephezulu ye-voltage positive. Ngenxa yalokho, ungqimba lwempushana yepulasitiki ifaka ngokushesha phezu kwendawo yokusebenza. Ngaphambi kokushaja, ungqimba lwe-powder lunamathela ngokuqinile. Ngemuva kokushisa nokupholisa, i-coat yepulasitiki efanayo ingatholakala.

Ukufafaza nge-powder electrostatic kwathuthukiswa maphakathi nawo-1960s futhi kulula ukuzenzela. Uma ukunamathela kungadingeki ukuba kube ugqinsi, ukufafaza kwe-electrostatic akudingi ukushisa kuqala kwe-workpiece, ngakho-ke ingasetshenziselwa izinto ezizwela ukushisa noma izinto zokusebenza ezingafanelekile ukufudumeza. Futhi ayidingi isitsha esikhulu sokugcina, esibalulekile ekufutheni kombhede omanzi. I-powder edlula i-workpiece ikhangwa ngemuva kwe-workpiece, ngakho-ke inani le-overspray lincane kakhulu kunezinye izindlela zokufafaza, futhi yonke i-workpiece ingagcotshwa ngokufafaza ohlangothini olulodwa. Kodwa-ke, ama-workpiece amakhulu asadinga ukufafazwa nhlangothi zombili.

Izinto zokusebenza ezineziphambano ezahlukene zingadala ubunzima ekushisiseni okulandelayo. Uma umehluko we-cross-section umkhulu kakhulu, ingxenye enkulu ye-coating ingase ingafinyeleli izinga lokushisa elincibilikayo, kanti ingxenye encane ingase isivele incibilikile noma yonakele. Kulokhu, ukuzinza okushisayo kwe-resin kubalulekile.

Izingxenye ezinamakhona angaphakathi ahlanzekile kanye nezimbobo ezijulile azimbozwa kalula ngokufafaza nge-electrostatic ngoba lezi zindawo zinezivikelo ze-electrostatic kanye ne-r.epel i-powder, ivimbela ukumboza ukungena emagumbini noma emigodini ngaphandle kokuthi isibhamu se-spray singafakwa kuzo. Ukwengeza, ukufafaza nge-electrostatic kudinga izinhlayiya ezingcono kakhulu ngoba izinhlayiya ezinkulu kungenzeka ziphume kucezu lokusebenza, futhi izinhlayiya ezicolekile kuno-150 mesh zisebenza kangcono esenzweni se-electrostatic.

Indlela yokugqoka encibilikayo eshisayo

Umgomo wokusebenza wendlela yokushisa encibilikayo ukufafaza i-powder yokugqoka epulasitiki endaweni yokusebenzela eshisiwe ngaphambili usebenzisa isibhamu sokufutha. Ipulasitiki iyancibilika ngokusebenzisa ukushisa kwendawo yokusebenza, futhi ngemva kokupholisa, ucwecwe lwepulasitiki lungasetshenziswa endaweni yokusebenza. Uma kunesidingo, ukwelashwa kwangemva kokushisa nakho kuyadingeka.

Isihluthulelo sokulawula inqubo ye-hot melt coating ukushisa kwangaphambi kokushisa kwe-workpiece. Uma izinga lokushisa langaphambi kokushisa liphezulu kakhulu, lingabangela i-oxidation enzima yendawo yensimbi, inciphise ukunamathela kokunamathela, futhi ingase ibangele ukubola kwe-resin kanye negwebu noma ukuguquguquka kombala. Uma izinga lokushisa langaphambi kokushisa liphansi kakhulu, i-resin ayinakugeleza kahle, okwenza kube nzima ukuthola i-coating efanayo. Imvamisa, isifutho esisodwa sendlela yokwemboza encibilikayo ayikwazi ukufeza ukushuba okufunayo, ngakho-ke kudingeka izifutho eziningi. Ngemuva kwesicelo ngasinye se-spray, ukwelashwa kokushisa kuyadingeka ukuze kuncibilike ngokuphelele futhi kukhanye ukugqoka ngaphambi kokusebenzisa ungqimba lwesibili. Lokhu akuqinisekisi nje kuphela ukugqoka okufanayo nokubushelelezi kodwa futhi kuthuthukisa kakhulu amandla omshini. Izinga lokushisa elinconywayo lokwelapha ukushisisa le-polyethylene ephezulu liba ngu-170°C, kanti ku-polyether e-chlorinated, liba ngu-200°C, ngesikhathi esinconywayo sehora elingu-1.

Indlela yokwemboza encibilikayo eshisayo ikhiqiza izembatho zekhwalithi ephezulu, ezithandekayo, eziboshwe ngokuqinile ezinokulahleka okuncane kwe-resin. Kulula ukuyilawula, inephunga elincane, futhi isibhamu sesifutho esisetshenzisiwe siyakwenza.

Ezinye izindlela ezitholakalayo zokumboza ipulasitiki ngensimbi

1. Ukufafaza: Gcwalisa ukumiswa endaweni yokugcina isibhamu sokufutha bese usebenzisa umoya ocindezelwe ngegauji yokucindezela okungeqile ku-0.1 MPa ukuze ufafaze ngokulinganayo okokunamathela phezu kwendawo yokusebenza. Ukuze unciphise ukulahlekelwa kokumiswa, umfutho womoya kufanele ugcinwe uphansi ngangokunokwenzeka. Ibanga phakathi kwe-workpiece kanye ne-nozzle kufanele igcinwe ku-10-20 cm, futhi indawo yokufafaza kufanele igcinwe i-perpendicular ekuqondeni kokugeleza kwezinto ezibonakalayo.

2. Ukucwiliswa: Gxilisa ucezu lomsebenzi ekumisweni imizuzwana embalwa, bese ulususa. Kuleli qophelo, ungqimba lokumiswa luzonamathela ebusweni bomsebenzi, futhi uketshezi oludlulele lungageleza phansi ngokwemvelo. Le ndlela ifanele ama-workpieces amancane adinga ukumbozwa okuphelele endaweni yangaphandle.

3. Ukuxubha: Ukuxubha kuhilela ukusebenzisa ibhulashi lokupenda noma ibhulashi ukuze usebenzise ukumiswa ebusweni bomsebenzi wokusebenza, ukudala ukunamathela. Ukuxubha kulungele ukumbozwa kwendawo okujwayelekile noma ukunamathela ohlangothini olulodwa ezindaweni eziwumngcingo. Nokho, akuvamile ukusetshenziswa ngenxa umphumela bushelelezi kancane ngisho surface ngemva kokuba enamathela omisiwe, kanye nomkhawulo on ukushuba ungqimba enamathela ngamunye.

4. Ukuthulula: Thela ukumiswa endaweni yokusebenza eyigodi ejikelezayo, uqinisekise ukuthi indawo engaphakathi imbozwe ngokuphelele ukumiswa. Bese, uthele uketshezi okweqile ukuze wenze i-coating. Le ndlela ilungele ukumboza ama-reactor amancane, amapayipi, izindololwane, ama-valve, ama-pump casings, ama-tee, nezinye izinto zokusebenza ezifanayo.

ngifuna ama-thermoplastic coatings ocingo lwensimbi

Le sayithi ye-inthanethi ingiphefumula, isakhiwo esihle ngempela nokuqukethwe okuphelele.

Ngicabanga ukuthi lolu ngolunye lwemininingwane ebaluleke kakhulu kimi. Futhi ngiyajabula ngokufunda isihloko sakho. Kodwa ngifuna ukusho ngezinto ezimbalwa ezivamile, Ukunambitheka kwesayithi kuphelele, izindatshana zinhle ngempela : D. Umsebenzi omuhle, cheers