Thermoplastic Powder Paint - Chaw tsim khoom, tsim kho, qhov zoo thiab qhov tsis zoo

Tsom

Tuam Tshoj PECOAT® tshwj xeeb hauv kev tsim khoom thiab xa tawm ntawm thermoplastic hmoov xim, cov khoom muaj polyethylene hmoov xim, pvc hmoov xim, nylon hmoov pleev, thiab fluidized txaj cov khoom siv dipping.

Kev txhim kho keeb kwm ntawm Thermoplastic Powder Xim

Txij li thaum muaj teeb meem roj hauv xyoo 1970s, cov hmoov txheej txheej tau tsim sai heev vim lawv cov peev txheej kev txuag, ib puag ncig tus phooj ywg, thiab tsim nyog rau kev tsim khoom. Thermoplastic hmoov xim (tseem hu ua thermoplastic hmoov txheej), ib qho ntawm ob hom xim hmoov xim, pib tshwm sim thaum xyoo 1930s.

Nyob rau xyoo 1940, nrog rau kev txhim kho ntawm kev lag luam petrochemical thiab lwm yam kev lag luam, kev tsim cov resins xws li polyethylene, polyvinyl chloride, thiab polyamide resin tau nce sai, ua rau kev tshawb fawb ntawm thermoplastic hmoov xim. Thaum xub thawj, tib neeg xav siv cov tshuaj tiv thaiv zoo ntawm polyethylene los siv rau txheej hlau. Txawm li cas los xij, polyethylene yog insoluble hauv cov kuab tshuaj thiab tsis tuaj yeem ua rau cov kuab tshuaj raws li txheej, thiab cov nplaum tsim nyog tsis pom los lo rau daim ntawv polyethylene rau cov hlau sab hauv. Yog li ntawd, cov nplaim hluav taws tau siv los yaj thiab txheej cov hmoov polyethylene ntawm cov hlau nto, yog li qhib qhov pib ntawm cov hmoov pleev xim thermoplastic.

Fluidized txaj txheej, uas yog tam sim no feem ntau siv thiab ntau txheej txheej txheej rau thermoplastic hmoov xim, pib nrog txoj kev ncaj qha sprinkling nyob rau hauv 1950. Nyob rau hauv no txoj kev, resin hmoov yog tusyees sprinkled nyob rau hauv rhuab nto ntawm lub workpiece los tsim ib txheej. Nyob rau hauv thiaj li yuav ua rau lub sprinkling txoj kev automated, lub fluidized txaj txheej txoj kev tau ntse sim nyob rau hauv lub teb chaws Yelemees nyob rau hauv 1952. Lub fluidized txaj txheej txoj kev siv cua los yog inert roj cua tshuab mus rau hauv lub ntxeem tau permeable phaj nyob rau hauv qab ntawm lub txaj fluidized los tsim ib tug uniformly faib. tawg khiav ri niab, uas ua rau cov hmoov nyob rau hauv lub fluidized txaj ntws mus rau hauv ib lub xeev nyob ze rau cov kua, yog li ntawd lub workpiece yuav muab sib npaug zos rau saum npoo ntawm workpiece thiab tau ib tug du thiab tiaj tus.

Hom thiab Pros thiab Cons ntawm Thermoplastic Powder Xim

Tam sim no, thermoplastic hmoov xim muaj ntau hom xws li polyethylene /polypropylene hmoov txheej, polyvinyl chloride hmoov txheej, nylon hmoov txheej, polytetrafluoroethylene hmoov txheej, thiab thermoplastic polyester hmoov txheej. Lawv tau siv dav hauv kev tiv thaiv kev tsheb, cov kav dej tiv thaiv corrosion, thiab ntau yam khoom siv hauv tsev.

polyethylene (PE) thiab polypropylene (PP) hmoov txheej

Polyethylene thiab polypropylene yog thawj cov ntaub ntawv siv hauv cov xim thermoplastic hmoov thiab yog ob qho tseem ceeb tshaj plaws thermoplastic polymers nyob rau hauv lub xyoo pua xeem. Tam sim no, ob qho tib si high-density thiab low-density polyethylene tau siv rau hauv cov thermoplastic teb. High-density polyethylene feem ntau yog siv nyob rau hauv kev lag luam teb, thaum tsawg-density polyethylene yog siv nyob rau hauv pej xeem teb.

Raws li cov saw molecular ntawm polyethylene thiab polypropylene yog carbon-carbon daim ntawv cog lus, ob leeg muaj cov yam ntxwv tsis-polar ntawm olefins, yog li polyethylene thiab polypropylene hmoov txheej muaj tshuaj lom neeg zoo thiab tau siv dav hauv kev tiv thaiv corrosion. Lawv yog siv los tiv thaiv, khaws cia, thiab thauj cov thawv, cov kav dej, thiab cov kav dej roj rau cov tshuaj thiab cov tshuaj reagents. Raws li cov khoom siv inert, hom hmoov xim no tsis zoo adhesion rau lub substrate thiab yuav tsum tau nruj nreem kev kho mob ntawm lub substrate, los yog daim ntawv thov ntawm primer los yog kev hloov ntawm polyethylene nrog rau lwm yam ntaub ntawv.

Advantage

Polyethylene resin yog feem ntau siv thiab ua cov tshuaj thermoplastic hmoov xim.

Nws muaj cov kev zoo hauv qab no:

- Kev tiv thaiv dej zoo heev, acid thiab alkali tsis kam, thiab tshuaj tiv thaiv;

- Zoo hluav taws xob rwb thaiv tsev thiab thermal rwb thaiv tsev zog;

- Lub zog tensile zoo heev, yoog raws, thiab cuam tshuam tsis kam;

- Kev ua haujlwm kub tsis zoo, tuaj yeem tswj tau 400 teev yam tsis muaj kev tawg ntawm -40 ℃;

- Tus nqi txheeb ze ntawm raw cov ntaub ntawv yog tsawg, tsis muaj tshuaj lom thiab ib puag ncig tus phooj ywg.

Disadvantage

Txawm li cas los xij, vim yog cov khoom ntawm cov khoom siv ntawm cov substrate polyethylene, polyethylene hmoov xim kuj muaj qee qhov tsis zoo:

- Lub hardness, hnav tsis kam, thiab mechanical zog ntawm txheej yog kuj tsis zoo;

- Lub adhesion ntawm lub txheej yog tsis zoo thiab lub substrate yuav tsum tau nruj me ntsis kho;

- Cov huab cua tsis zoo, ua rau muaj kev ntxhov siab tawg tom qab raug ultraviolet rays;

- Tsis zoo kub-kub tsis kam thiab tsis zoo ua hauj lwm rau humid cua sov.

Polyvinyl chloride (PVC) hmoov txheej

Polyvinyl chloride (PVC) yog ib qho amorphous polymer uas muaj me me ntawm cov muaju tsis tiav. Feem ntau PVC Cov khoom lag luam muaj qhov hnyav molecular ntawm 50,000 thiab 120,000. Txawm tias siab molecular hnyav PVC resins muaj lub cev zoo dua qub, qhov hnyav molecular tsawg PVC resins nrog qis yaj viscosity thiab softening kub yog ntau haum raws li cov ntaub ntawv rau thermoplastic hmoov xim.

PVC nws tus kheej yog cov khoom siv nruj thiab tsis tuaj yeem siv los ua cov hmoov pleev xim ib leeg. Thaum ua cov txheej txheem, ib qho nyiaj ntawm plasticizer yuav tsum tau muab ntxiv los kho qhov yooj yim ntawm PVC. Nyob rau tib lub sijhawm, ntxiv plasticizers kuj txo cov khoom siv lub zog tensile, modulus, thiab hardness. Xaiv cov khoom tsim nyog thiab tus nqi ntawm plasticizer tuaj yeem ua tiav qhov xav tau sib npaug ntawm cov khoom yooj yim thiab hardness.

Rau qhov ua tiav PVC hmoov pleev xim mis, stabilizers kuj yog ib feem tseem ceeb. Los daws qhov thermal stability ntawm PVC, sib tov ntsev ntawm calcium thiab zinc nrog zoo thermal stability, barium thiab cadmium soaps, mercaptan tin, dibutyltin derivatives, epoxy compounds, thiab lwm yam. Txawm hais tias txhuas stabilizers muaj thermal stability zoo, lawv tau raug phased tawm ntawm kev ua lag luam vim ib puag ncig yog vim li cas.

Tam sim no, cov khoom siv feem ntau siv rau PVC hmoov xim yog ntau yam khoom siv hauv tsev thiab lub tshuab ntxuav tais diav. PVC cov khoom muaj kev ntxuav zoo thiab ua haujlwm tsis zoo rau cov khoom noj. Lawv tuaj yeem txo cov suab nrov rau cov tais diav. Cov tais diav coated nrog PVC cov khoom yuav tsis ua suab nrov thaum tso tableware. PVC hmoov txheej tuaj yeem siv los ntawm kev tsim kho lub txaj fluidized lossis electrostatic txau, tab sis lawv xav tau cov hmoov sib txawv. Nws yuav tsum tau muab sau tseg tias PVC hmoov xim emit ib tug pungent tsw thaum lub sij hawm immersion txheej thiab muaj teeb meem rau tib neeg lub cev. Lawv cov kev siv twb pib raug txwv nyob rau hauv txawv teb chaws.

Advantage

Qhov zoo ntawm polyvinyl chloride hmoov xim yog:

- Tus nqi raw khoom tsawg;

- Kev ua qias tuaj zoo, ntxuav tsis kam, thiab corrosion kuj;

- High mechanical zog thiab zoo hluav taws xob rwb thaiv tsev kev ua tau zoo.

Disadvantage

Qhov tsis zoo ntawm polyvinyl chloride hmoov xim yog:

- Qhov kub sib txawv ntawm melting kub thiab decomposition kub ntawm PVC resin me me. Thaum lub sij hawm txheej txheej txheej, qhov kub thiab txias yuav tsum tau tswj nruj me ntsis kom tiv thaiv cov txheej los ntawm decomposing.

- Cov txheej tsis tiv taus cov tshuaj tsw qab hydrocarbons, esters, ketones, thiab cov kuab tshuaj chlorinated, thiab lwm yam.

Polyamide (nylon) hmoov txheej

Polyamide resin, feem ntau hu ua nylon, yog siv dav siv thermoplastic cob. Nylon muaj cov khoom zoo tshaj plaws, siab hardness, thiab zoo heev hnav tsis kam. Cov dynamic thiab zoo li qub kev sib txhuam coefficients ntawm nylon txheej yog me me, thiab lawv muaj lubricity. Yog li ntawd, lawv yog siv nyob rau hauv textile machinery bearings, zog, li qub, thiab lwm yam. Nylon hmoov txheej muaj zoo lubrication, tsis muaj suab nrov, zoo yooj, zoo heev adhesion, tshuaj tsis kam, thiab hnyav kuj. Lawv tuaj yeem siv los ua qhov zoo tagnrho hnav-tiv taus thiab lubricating txheej los hloov tooj liab, txhuas, cadmium, hlau, thiab lwm yam. Qhov ntom ntawm nylon txheej zaj duab xis tsuas yog 1/7 ntawm tooj liab, tab sis nws hnav tsis kam yog yim npaug ntawm tooj liab.

Nylon hmoov txheej yog non-toxic, tsw, thiab tasteless. Ua ke nrog qhov tseeb tias lawv tsis raug cuam tshuam los ntawm fungal ntxeem tau lossis txhawb kev loj hlob ntawm cov kab mob, lawv tau ua tiav rau kev lag luam ua zaub mov kom cov txheej txheem tshuab thiab cov raj xa dej los yog cov txheej txheem ntawm cov khoom siv los ntawm cov khoom noj. Vim nws cov dej zoo heev thiab dej ntsev, nws kuj yog siv rau txheej tshuab ntxhua khaub ncaws, thiab lwm yam.

Ib qho tseem ceeb ntawm daim ntawv thov ntawm nylon hmoov txheej yog txheej txheej ntau yam ntawm tes, tsis tsuas yog vim lawv muaj cov yam ntxwv tseem ceeb xws li hnav tsis kam thiab khawb tsis kam, tab sis kuj vim tias lawv cov thermal conductivity tsawg ua rau cov leeg muag muag. Qhov no ua rau cov ntaub ntawv no zoo heev rau txheej cov cuab yeej tuav, qhov rooj tuav, thiab lub kauj tsheb.

Piv nrog rau lwm cov txheej txheej, nylon txheej zaj duab xis muaj cov tshuaj tsis zoo thiab tsis haum rau kev siv tshuaj lom neeg xws li acids thiab alkalis. Yog li ntawd, qee cov epoxy resins feem ntau tau ntxiv los ua cov hloov kho, uas tuaj yeem tsis tsuas yog txhim kho corrosion kuj ntawm nylon txheej, tab sis kuj txhim kho lub zog sib txuas ntawm cov zaj duab xis txheej thiab cov hlau substrate. Nylon hmoov muaj qhov nqus dej siab thiab muaj kev cuam tshuam rau cov dej noo thaum siv thiab khaws cia. Yog li ntawd, nws yuav tsum tau muab khaws cia rau hauv qhov chaw kaw thiab yuav tsum tsis txhob siv rau lub sijhawm ntev nyob rau hauv cov av noo thiab kub. Lwm qhov yuav tsum tau nco ntsoov yog tias lub sij hawm plasticizing ntawm cov hmoov nylon yog luv luv, thiab txawm tias cov yeeb yaj kiab txheej uas tsis xav tau plasticizing tuaj yeem ua tiav cov nyhuv xav tau, uas yog qhov tshwj xeeb ntawm cov hmoov nylon.

Polyvinylidene fluoride (PVDF) hmoov xim

Cov neeg sawv cev tshaj plaws ntawm huab cua-tiv thaiv txheej hauv cov xim pleev xim yog polyvinylidene fluoride (PVDF) hmoov txheej. Raws li tus neeg sawv cev tshaj plaws huab cua-resistant ethylene polymer, PVDF muaj cov khoom siv zoo thiab muaj kev cuam tshuam, hnav tsis kam, zoo heev yooj thiab hardness, thiab tuaj yeem tiv taus cov tshuaj corrosive feem ntau xws li acids, alkalis, thiab muaj zog oxidants. Ntxiv mus, nws yog insoluble nyob rau hauv cov tshuaj solvents feem ntau siv nyob rau hauv lub coatings kev lag luam, uas yog vim lub FC bonds muaj nyob rau hauv PVDF. Tib lub sijhawm, PVDF kuj ua tau raws li FDA cov cai thiab tuaj yeem siv rau hauv kev ua zaub mov thiab tuaj yeem sib cuag nrog cov zaub mov.

Vim nws cov viscosity siab melting, PVDF yog feem ntau rau pinholes thiab tsis zoo hlau adhesion nyob rau hauv nyias zaj duab xis txheej, thiab cov khoom nqi yog siab dhau. Yog li ntawd, feem ntau, nws tsis yog siv los ua ib qho khoom siv rau cov hmoov coatings. Feem ntau, txog 30% ntawm acrylic resin yog ntxiv los txhim kho cov khoom no. Yog tias cov ntsiab lus ntawm acrylic resin siab dhau lawm, nws yuav cuam tshuam rau huab cua tsis kam ntawm txheej zaj duab xis.

Qhov ci ntawm PVDF txheej zaj duab xis yog qhov tsawg, feem ntau nyob ib ncig ntawm 30 ± 5%, uas txwv nws daim ntawv thov hauv kev kho kom zoo nkauj. Tam sim no, nws yog siv los ua lub tsev txheej rau cov tsev loj, siv rau lub ru tsev panels, phab ntsa, thiab extruded aluminium qhov rais thav ntawv, nrog rau huab cua tsis zoo heev.

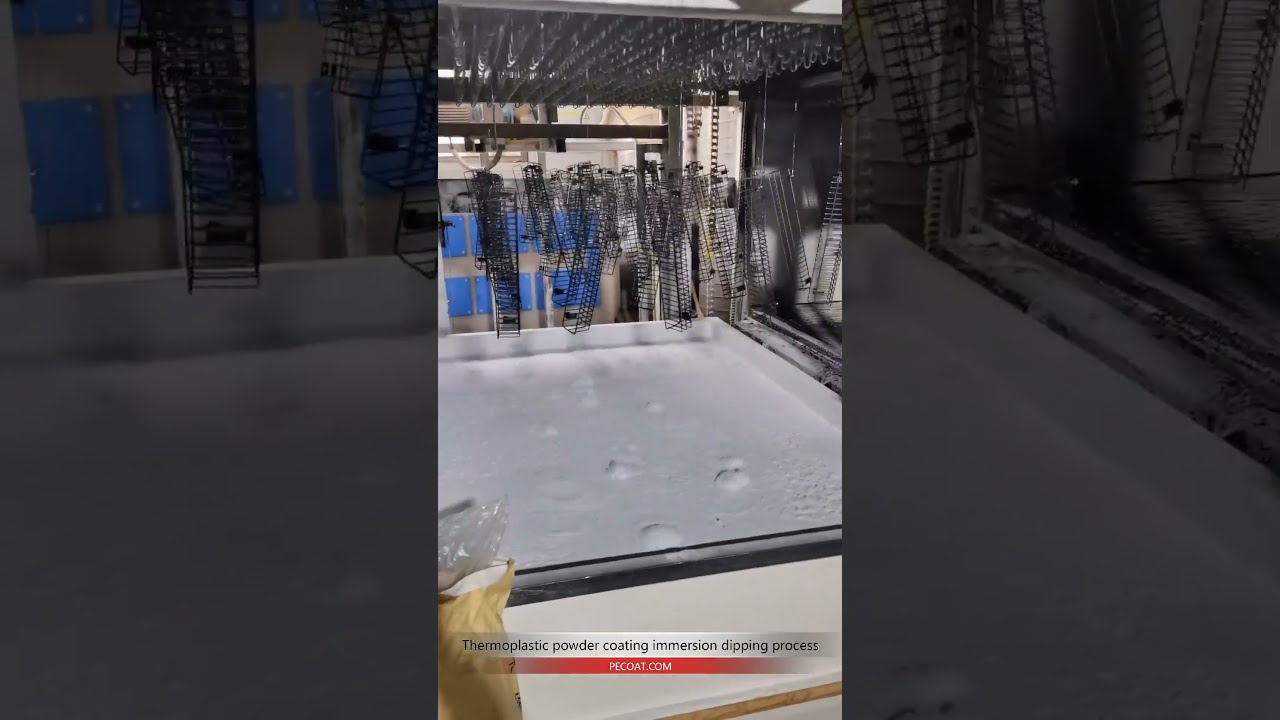

Siv Video

Ua tsaug rau koj txoj kev pab thiab rau kev sau ntawv no txog cov hmoov pleev xim. Nws ua tau zoo heev.