Ihe mkpuchi plastik Maka igwe

Ihe mkpuchi plastik maka usoro ígwè bụ itinye ihe mkpuchi plastik n'elu akụkụ nke ígwè, nke na-enye ha ohere ijigide àgwà mbụ nke ígwè ma na-enye ụfọdụ ihe onwunwe nke plastik, dị ka nkwụsị nke corrosion, mkpuchi mkpuchi, mkpuchi eletrik na onwe ya. - mmanu mmanu. Usoro a dị oke mkpa na ịgbasa ngwa ngwa nke ngwaahịa na ịkwalite uru akụ na ụba ha.

Ụzọ maka mkpuchi plastik maka ígwè

Enwere ọtụtụ ụzọ maka mkpuchi plastik, gụnyere ịgbasa ire ọkụ, mmiri mmiri bed spraying, ntụ ntụ electrostatic spraying, ọkụ gbazee mkpuchi, na nkwusioru mkpuchi. E nwekwara ọtụtụ ụdị plastik nke enwere ike iji maka mkpuchi, ya PVC, PE, na PA bụ ihe a na-ejikarị eme ihe. Plastic a na-eji maka mkpuchi ga-adị n'ụdị ntụ ntụ, nke dị mma nke 80-120 mesh.

Mgbe mkpuchi, ọ kacha mma ngwa ngwa ajụkwa workpiece site n'itinye ya na mmiri oyi. Ngwa ngwa jụrụ oyi nwere ike ibelata kristal nke mkpuchi plastik, mee ka ọdịnaya mmiri dịkwuo elu, melite ike na nchapụta elu nke mkpuchi ahụ, na-eme ka adhesion dịkwuo elu, na imeri mkpuchi mkpuchi nke nrụgide dị n'ime.

Iji meziwanye adhesion n'etiti mkpuchi na isi metal, elu nke workpiece kwesịrị ịbụ uzuzu-free na akọrọ, na-enweghị nchara na griiz tupu mkpuchi. N'ọtụtụ ọnọdụ, workpiece kwesịrị ịga ọgwụgwọ elu. Ụzọ ọgwụgwọ gụnyere ịgba aja, ọgwụgwọ kemịkalụ, na ụzọ ndị ọzọ na-arụ ọrụ. N'ime ha, sandblasting nwere mmetụta dị mma ka ọ na-eme ka ọ dị elu nke ọrụ ahụ, na-amụba elu elu ma na-akpụ nko, si otú ahụ na-eme ka adhesion dịkwuo mma. Mgbe sandblasting gasịrị, a ga-eji ikuku a na-ekpo ọkụ na-ekpo ọkụ na-arụ ọrụ na-arụ ọrụ iji wepụ uzuzu, na plastik kwesịrị ka a na-ekpuchi ya n'ime awa 6, ma ọ bụghị ya, elu ahụ ga-eme ka oxidize, na-emetụta adhesion nke mkpuchi.

Advantage

Mkpuchi ozugbo na plastik powdered nwere uru ndị a:

- Enwere ike iji ya na resins nke dị naanị n'ụdị ntụ ntụ.

- Enwere ike nweta mkpuchi siri ike n'otu ngwa.

- Ngwaahịa nwere ụdị dị mgbagwoju anya ma ọ bụ ọnụ ọnụ dị nkọ nwere ike kpuchie ya nke ọma.

- Ọtụtụ plastik powdered nwere ezigbo nkwụsi ike nchekwa.

- Enweghị ihe mgbaze achọrọ, na-eme ka usoro nkwadebe ihe dị mfe. Otú ọ dị, e nwekwara ụfọdụ ihe ndọghachi azụ ma ọ bụ njedebe na mkpuchi ntụ ntụ. Dị ka ihe atụ, ọ bụrụ na workpiece kwesịrị preheated, ya size ga-ejedebeghị. N'ihi na usoro mkpuchi na-ewe oge, n'ihi na nnukwu-sized workpieces, mgbe spraying ka agwụbeghị, ụfọdụ ebe ama mma n'okpuru chọrọ okpomọkụ. N'oge usoro mkpuchi ntụ ntụ plastik, mfu ntụ ntụ nwere ike ịdị elu dị ka 60%, ya mere a ghaghị ịnakọta ya ma jiri ya mee ihe iji gboo mkpa akụ na ụba.

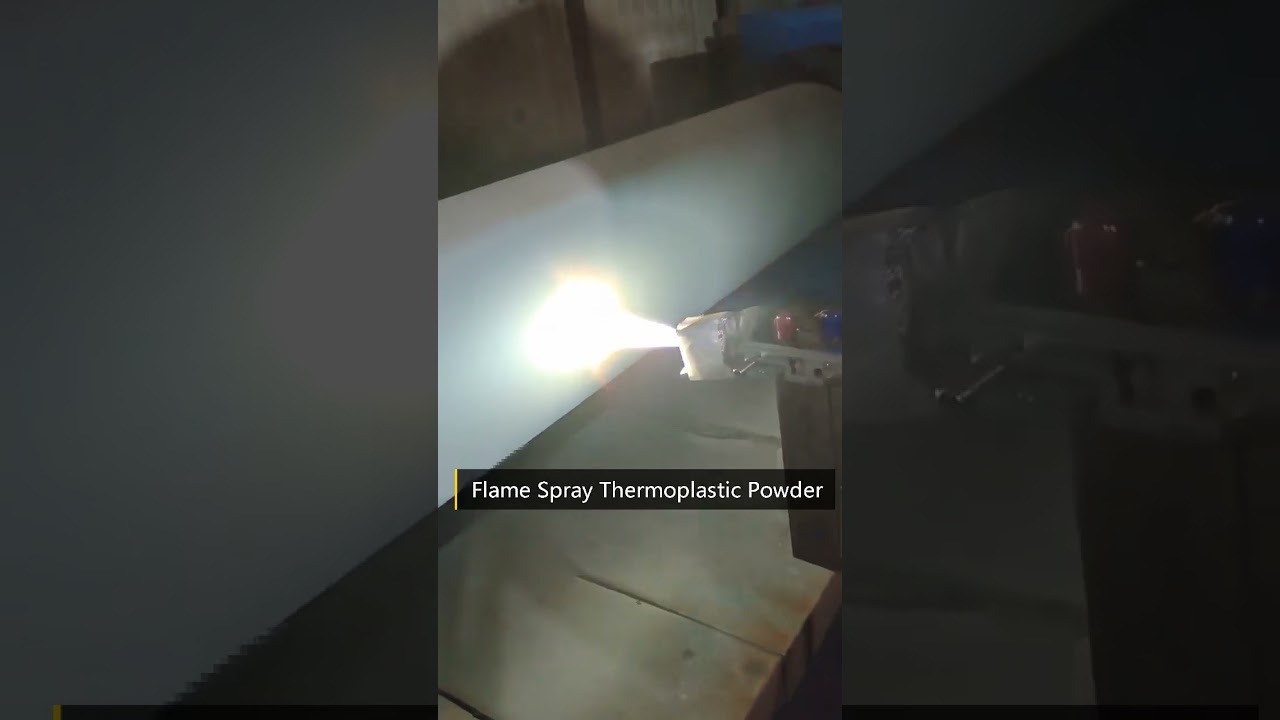

Ire ọkụ

Ihe mkpuchi rọba na-efesa ire ọkụ maka ọla bụ usoro na-agụnye ịgbaze ma ọ bụ gbazee uzuzu ma ọ bụ plastik pasty na ire ọkụ na-esi na egbe na-efesa, wee fesa plastik a wụrụ awụ n'elu ihe iji mee mkpuchi rọba. Ọkpụrụkpụ nke mkpuchi na-abụkarị n'etiti 0.1 na 0.7 mm. Mgbe ị na-eji plastik powdered maka ịgbasa ire ọkụ, a ga-ebu ụzọ kpoo workpiece ahụ. Enwere ike ịme ọkụ ọkụ na oven, okpomọkụ na-ekpo ọkụ dị iche iche depending na ụdị plastik a na-efesa.

A ghaghị ịchịkwa ọkụ ọkụ n'oge ịgba mmiri, n'ihi na oke okpomọkụ nwere ike ịgba ọkụ ma ọ bụ mebie plastik, ebe oke okpomọkụ nwere ike imetụta adhesion. N'ozuzu, okpomọkụ kachasị elu mgbe ị na-agbanye akwa akwa mbụ nke rọba, nke nwere ike imeziwanye nrapado n'etiti ígwè na plastik. Ka a na-efesa n'ígwé ndị na-esote, okpomọkụ nwere ike belata ntakịrị. Ebe dị anya n'etiti egbe ịgba na workpiece kwesịrị ịdị n'etiti 100 na 200 cm. N'ihi na ewepụghị workpieces, na workpiece kwesịrị idobe horizontally na ịgba egbe kwesịrị ịkwaga azụ na pụta; maka cylindrical ma ọ bụ esịtidem mụụrụ workpieces, ha ga-n'ịnyịnya na a lathe maka rotational spraying. Ọsọ ahịrị ahịrị nke workpiece na-atụgharị kwesịrị ịdị n'etiti 20 na 60 m / min. Mgbe emechara ihe mkpuchi ahụ achọrọ, a ga-akwụsị ịgbasa ma na-arụ ọrụ ahụ ga-aga n'ihu na-atụgharị ruo mgbe plastik a wụrụ awụ siri ike, mgbe ahụ, ọ ga-adị mma ngwa ngwa.

Ọ bụ ezie na ire ọkụ spraying nwere a dịtụ ala mmepụta arụmọrụ na-agụnye ojiji nke mgbakasị gas, ọ ka bụ ihe dị mkpa nhazi usoro na ụlọ ọrụ n'ihi na ya ala akụrụngwa ego na irè na mkpuchi nke interiors nke tankị, containers, na nnukwu workpieces tụnyere ndị ọzọ ụzọ. .

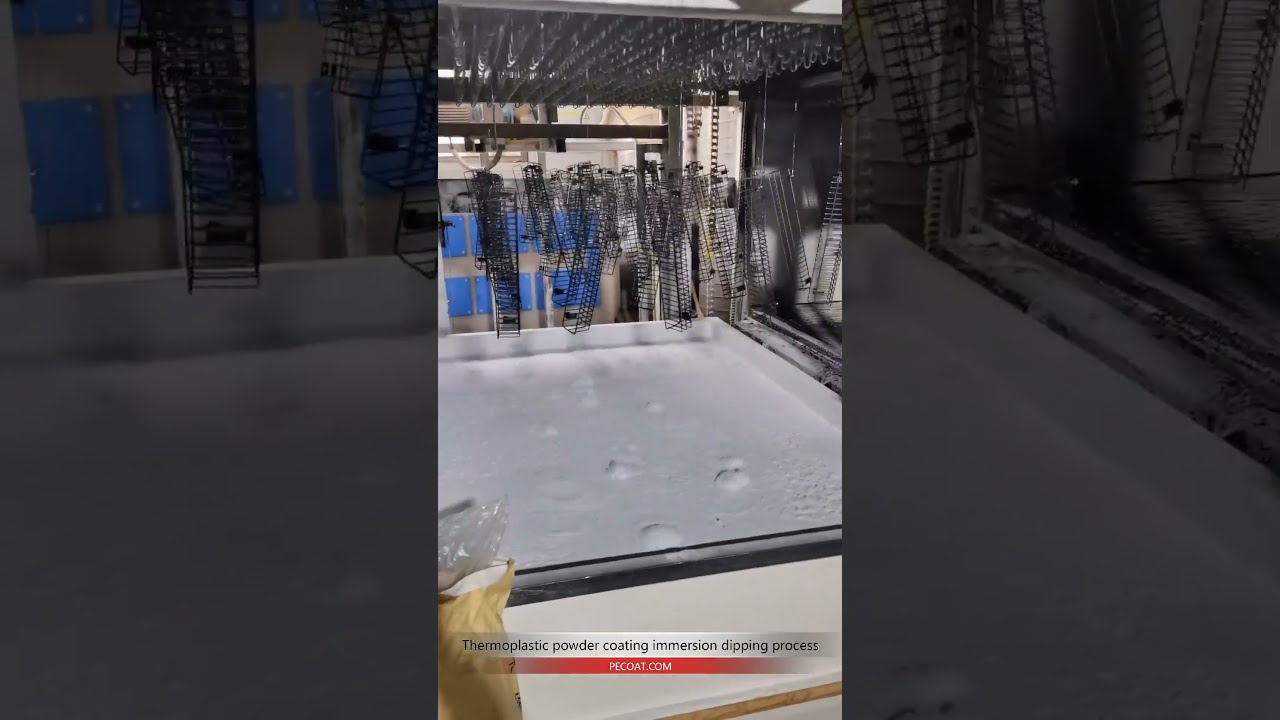

Ihe mkpuchi akwa akwa mmiri nwere mmiri mmiri

Ụkpụrụ na-arụ ọrụ nke ihe mkpuchi akwa akwa akwa mmiri maka metal bụ nke a: A na-etinye ntụ ntụ plastik n'ime akpa cylindrical na nkebi porous n'elu nke na-enye ohere naanị ikuku na-agafe, ọ bụghị ntụ ntụ. Mgbe ikuku abịakọrọ na-esi na ala nke akpa ahụ na-abanye, ọ na-afụ uzuzu elu ma kwụsịtụ ya n'ime akpa ahụ. Ọ bụrụ na a na-emikpu n'ime ya, resin ntụ ntụ ga-agbaze ma rapara na workpiece, na-akpụ mkpuchi.

The ọkpụrụkpụ nke mkpuchi nwetara na fluidized bed depends na okpomọkụ, kpọmkwem ike okpomọkụ, ọnụọgụ elu, oge ịgba, na ụdị plastik eji mgbe workpiece na-abanye n'ime ụlọ mmiri. Otú ọ dị, naanị okpomọkụ na oge ịgba nke workpiece nwere ike ịchịkwa na usoro, na ha kwesịrị ikpebi site nnwale na mmepụta.

N'oge ntinye, a na-achọrọ ka uzuzu rọba na-aga nke ọma na nke ọma, na-enweghị agglomeration, vortex eruba, ma ọ bụ oke mgbasa nke ihe ahụ plastik. Ekwesịrị ịme usoro ndị dabara adaba iji mezuo ihe ndị a chọrọ. Ịgbakwunye ngwaọrụ na-akpali akpali nwere ike ibelata agglomeration na vortex eruba, ebe ị na-agbakwunye obere ntụ ntụ talcum na ntụ ntụ plastik bara uru maka ịmịcha mmiri, ma ọ nwere ike imetụta àgwà mkpuchi. Iji gbochie mgbasa nke ihe ndị dị na plastik, a ghaghị ịchịkwa ọnụ ọgụgụ ikuku na ịdị n'otu nke ihe ndị dị na plastik. Otú ọ dị, ụfọdụ mgbasa ozi bụ ihe a na-apụghị izere ezere, ya mere a ga-etinye ngwaọrụ mgbake na akụkụ elu nke akwa mmiri.

Uru nke mkpuchi mkpuchi akwa akwa akwa mmiri bụ ikike ịkwanye ihe arụ ọrụ dị mgbagwoju anya, mma mkpuchi dị elu, nweta mkpuchi siri ike n'otu ngwa, mfu resin pere mpe, yana ebe ọrụ dị ọcha. Mwepu bụ ihe isi ike nke nhazi nnukwu workpieces.

Electrostatic spraying plastic mkpuchi maka metal

Na electrostatic spraying, resin plastic mkpuchi ntụ ntụ na-edokwa n'elu nke workpiece site electrostatic ike, kama site na agbaze ma ọ bụ sintering. Ụkpụrụ bụ iji ubi electrostatic kpụrụ site na elu-voltaji electrostatic generator na-ana resin ntụ ntụ sprayed si spray egbe na static ọkụ eletrik, na n'ala workpiece na-aghọ elu-voltaji nti electrode. N'ihi ya, otu oyi akwa nke edo edo ntụ ntụ na-etinye ngwa ngwa n'elu ihe ahụ. Tupu ebubo ahụ agbasa, oyi akwa ntụ ntụ na-ejidesi ike. Mgbe kpochara ma mee ka ọ dị jụụ, enwere ike nweta ihe mkpuchi plastik edo edo.

E mepụtara spraying electrostatic ntụ ntụ n'etiti afọ 1960 ma dị mfe iji rụọ ọrụ. Ọ bụrụ na mkpuchi ahụ adịghị mkpa ka ọ dị oke, electrostatic spraying anaghị achọ preheating nke workpiece, n'ihi ya, ọ nwere ike na-eji maka okpomọkụ-enwe mmetụta ihe ma ọ bụ workpieces na-adịghị mma maka kpo oku. Ọ dịghịkwa achọ nnukwu nchekwa nchekwa, nke dị mkpa na ịgbasa akwa akwa mmiri. A na-adọta ntụ ntụ nke na-agafe na workpiece na azụ nke workpiece, ya mere ọnụ ọgụgụ nke overspray dị ntakịrị karịa na ụzọ ndị ọzọ spraying, na ihe niile workpiece nwere ike ntekwasa site spraying n'otu akụkụ. Otú ọ dị, nnukwu workpieces ka kwesịrị sprayed si n'akụkụ abụọ.

Ihe eji arụ ọrụ nwere akụkụ obe dị iche iche nwere ike ibute ihe isi ike maka kpo oku na-esote. Ọ bụrụ na ọdịiche dị na mpaghara obe buru ibu, akụkụ dị arọ nke mkpuchi ahụ nwere ike ọ gaghị erute okpomọkụ na-agbaze, ebe nke dị nro nwere ike ịgbaze ma ọ bụ mebie ya. N'okwu a, nkwụsi ike nke okpomọkụ nke resin dị mkpa.

Ngwa ndị nwere akụkụ dị n'ime ya na oghere miri emi adịghị ekpuchi ya ngwa ngwa site na spraying electrostatic n'ihi na mpaghara ndị a nwere mkpuchi electrostatic na r.epel ntụ ntụ, na-egbochi mkpuchi ịbanye n'akụkụ ma ọ bụ oghere ọ gwụla ma enwere ike itinye egbe ịgba n'ime ha. Na mgbakwunye, spraying electrostatic na-achọ ihe ndị dị mma n'ihi na ihe ndị buru ibu nwere ike ịwepụ na workpiece, na ihe ndị dị mma karịa 150 ntupu na-arụ ọrụ nke ọma na ọrụ electrostatic.

Usoro mkpuchi agbaze ọkụ

Ụkpụrụ na-arụ ọrụ nke usoro mkpuchi na-ekpo ọkụ na-ekpo ọkụ bụ ịgbasa ntụ ntụ plastik n'elu ebe a na-ekpo ọkụ na-ekpo ọkụ na-eji egbe ịgba. The plastic agbaze site tinye n'ọrụ okpomọkụ nke workpiece, na mgbe jụrụ oyi, a plastic mkpuchi nwere ike itinye na workpiece. Ọ bụrụ na ọ dị mkpa, a na-achọkwa ọgwụgwọ ọkụ ọkụ.

Isi ihe na-achịkwa usoro mkpuchi mkpuchi na-ekpo ọkụ bụ preheating okpomọkụ nke workpiece. Mgbe ikpo ọkụ na-ekpo ọkụ dị oke elu, ọ nwere ike ime ka oxidation siri ike nke elu igwe, belata nchikota nke mkpuchi ahụ, na ọbụna mee ka resin decomposition na ụfụfụ ma ọ bụ gbanwee nke mkpuchi. Mgbe okpomoku na-ekpo ọkụ dị oke ala, resin enweghị ike ịgbasa, na-eme ka o sie ike ịnweta mkpuchi otu. Ọtụtụ mgbe, otu ngwa ịgbanye nke usoro mkpuchi na-ekpo ọkụ na-ekpo ọkụ enweghị ike iru oke achọrọ, ya mere a na-achọ ọtụtụ ngwa ịgba. Mgbe ọ bụla ịgbasa ngwa ngwa, ọgwụgwọ kpo oku dị mkpa iji gbazee kpamkpam ma mee ka mkpuchi ahụ dịkwuo mma tupu itinye akwa oyi akwa nke abụọ. Nke a ọ bụghị nanị na-eme ka a edo na-eji ire ụtọ mkpuchi ma budata mma n'ibu ike. A na-atụ aro ikpo ọkụ ọgwụgwọ okpomọkụ maka polyethylene dị elu dị gburugburu 170 ° C, na maka polyether chlorinated, ọ dị gburugburu 200 Celsius, na oge a tụrụ aro ya bụ 1 hour.

Usoro mkpuchi na-ekpo ọkụ na-ekpo ọkụ na-emepụta ihe dị elu, nke na-adọrọ mmasị, ihe mkpuchi siri ike nke nwere obere mfu resin. Ọ dị mfe ịchịkwa, nwee obere isi, na egbe ịgba a na-eji na-eme ya.

Ụzọ ndị ọzọ dị maka mkpuchi plastik maka ígwè

1. Ịfesa: Jupụta nkwusioru n'ime ịgba mmiri mmiri na-eji ikuku abịakọrọ na a nlele mgbali adịghị gafere 0.1 MPa ka evenly fesa mkpuchi n'elu nke workpiece. Iji belata nkwụsị nkwusioru, ikuku ikuku kwesịrị idowe obere ka o kwere mee. Ebe dị anya n'etiti workpiece na nozzle kwesịrị ịnọgide na-enwe na 10-20 cm, na spraying elu kwesịrị idobe perpendicular na ntụziaka nke ihe eruba.

2. imikpu: Na-emikpu workpiece na nkwusioru maka sekọnd ole na ole, wee wepụ ya. N'oge a, oyi akwa nke nkwusioru ga-arapara n'elu nke workpiece, na ngafe mmiri mmiri nwere ike na-agbada n'ụzọ nkịtị. Usoro a dabara adaba maka obere ọrụ nke na-achọ mkpuchi zuru oke na elu mpụga.

3. Nchacha: ịhịa aka n'ahụ na-agụnye iji brọsh agba ma ọ bụ ahịhịa iji tinye nkwusioru ahụ n'elu ọrụ ahụ, na-emepụta mkpuchi. Ahịhịa kwesịrị ekwesị maka mkpuchi mpaghara mpaghara ma ọ bụ mkpuchi otu akụkụ na mbara ala dị warara. Otú ọ dị, a na-ejikarị ya eme ihe n'ihi ihe na-esi na ya pụta na-adịchaghị mma na ọbụna n'elu mgbe a kpochapụrụ mkpuchi ahụ, na njedebe na oke nke mkpuchi mkpuchi ọ bụla.

4. Ịwụ: Wunye nkwusioru n'ime a na-atụgharị oghere oghere workpiece, hụ na n'ime elu na-kpamkpam kpuchie site nkwusioru. Mgbe ahụ, wụpụ mmiri mmiri na-adịghị mma iji mepụta mkpuchi. Usoro a dabara adaba maka mkpuchi obere reactors, pipeline, elbows, valves, casings pump, tees, na ndị ọzọ yiri workpieces.

Ana m achọ mkpuchi thermoplastic maka waya igwe

Saịtị ịntanetị a bụ ihe na-eku ume, ezigbo nhazi na ọdịnaya zuru oke.

Echere m na nke a bụ otu n'ime ozi dị oke mkpa nye m. Obi dịkwa m ụtọ ịgụ akụkọ gị. Ma na-achọ ikwu okwu na ole na ole nkịtị ihe, The saịtị uto zuru okè, isiokwu bụ n'ezie oké : D. Good job, cheers