PECOAT Polyethylene Powder Coating for Drinking Water Pipeline

PECOAT® Polyethylene Powder Coating for Drinking Water Pipelines And Water Supply Equipment

Description

Drinking water dedicated polyethylene powder coating is a thermoplastic powder coating prepared from polyethylene resin, compatibilizer, functional additives, pigments and fillers. It has been fully tested and evaluated for hygiene and safety, and can be used for coating of ambient temperature drinking water supply equipment and pipelines. It has good chemical stability, electrical insulation and low temperature resistance, as well as excellent corrosion resistance and durability. The product complies with the CJ/T 120-2016 “Urban Construction Industry Standard” of the People’s Republic of China.

Application Field

Coating suitable for ambient temperature drinking water supply equipment and pipelines.

Powder Properties

- Non-volatile content: ≥99.5%

- Dry flowability: 20%

- Specific gravity: 0.91-0.95 (varies with color)

- Particle size distribution: ≤300um

- Melt index: 5-20g/10min (2.16kg, 190℃) [depending on coating workpiece and customer process]

- Storage: indoors below 35℃, ventilated and dry, away from fire sources. The storage period is two years from the date of production. After expiration, it can still be used if it passes retesting. It is also recommended to follow the first-in-first-out principle for product use.

- Packaging: composite paper bag packaging, with a net weight of 20 kg per bag.

Application Instructions

- Pre-treatment: Before coating, the base pipe must be treated with processes such as sandblasting or acid pickling and phosphating to remove rust, oil, and oxide film on the surface of the base metal and the galvanized layer.

- Workpiece preheating temperature: 230-280℃ [adjusted according to the pipe diameter].

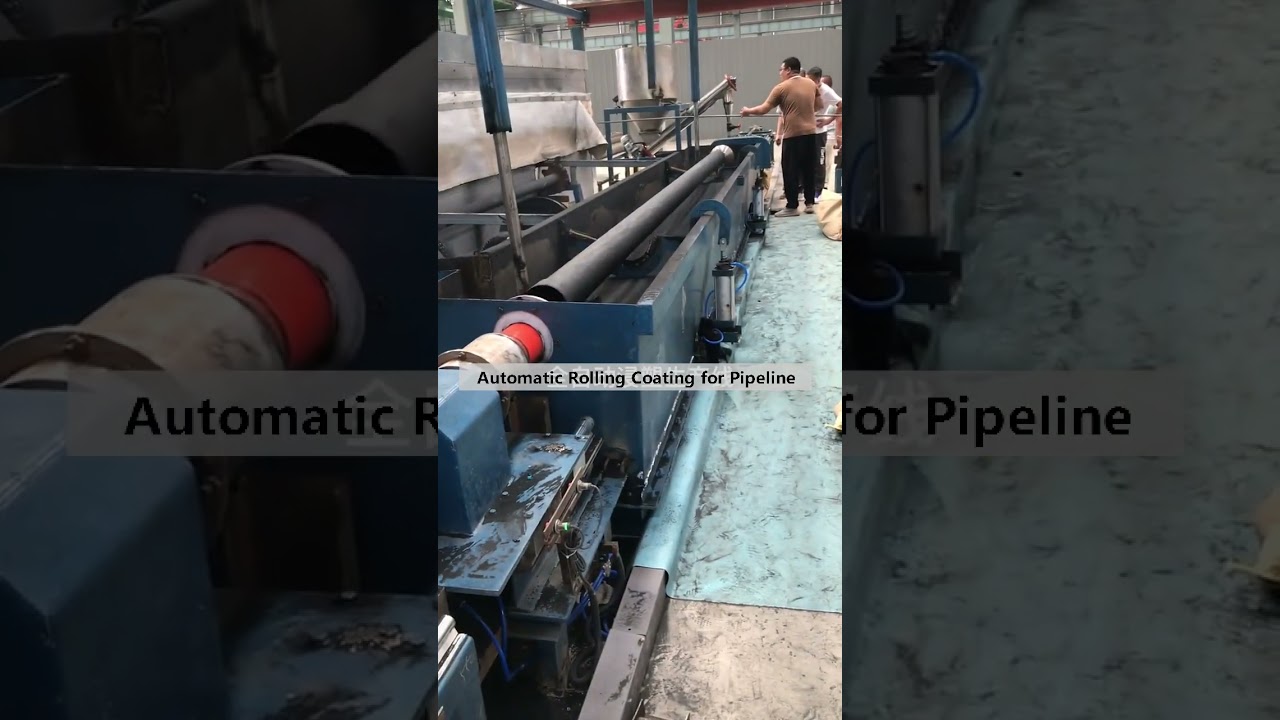

- Coating method: vacuum suction coating or rolling coating.

- Post-heat: 180-220℃, 0-5 minutes [determine the plasticization process according to the pipe diameter and coating smoothness. Heating and plasticizing is beneficial to obtain a smooth coating on the surface of the metal workpiece].

- Cooling: air-cooled or natural cooling.

Caution

1. To achieve optimal adhesion, it is recommended to perform phosphating or chromizing treatment on the base material after degreasing and rust removal.

2. Overheating will cause aging and discoloration of the coating, while too low temperature will result in poor powder coverage and uneven coating. Therefore, the optimal heating temperature should be determined through experiments based on the metal thickness and customer coating facilities.

3. Workpiece design: sharp parts should be smoothed, and there should be no gaps at the welding joints. The metal thickness and wire diameter on the same workpiece should be similar.

4. This product is not recommended for use in post-processing (reforming coated workpieces).

5. Like all polymer powders, especially in flowing conditions, this powder can ignite or burn when in contact with a heat source or ignition device.

Leave a Reply