Category: Thermoplastic Powder Paint

Thermoplastic powder paint is a type of coating process that involves applying a dry powder paints of thermoplastic material onto a substrate, usually a metal surface. The powder is heated until it melts and forms a continuous, protective coating. This coating process can be done using several techniques, including electrostatic spraying and fluidized bed dipping.

Thermoplastic powder paints offers several advantages over traditional liquid coatings, including:

- Durability: Thermoplastic paints are highly durable and resistant to impact, abrasion, and chemicals, making them ideal for use in harsh environments.

- Ease of application: Thermoplastic powder paints can be applied more easily and uniformly than liquid coatings, which can help to reduce material waste and improve efficiency.

- Cost-effectiveness: Because thermoplastic paints can be applied more efficiently, they can often be less expensive than liquid coatings in the long run.

- Environmental friendliness: Thermoplastic paints are free of volatile organic compounds (VOCs), which can make them a more environmentally friendly alternative to liquid coatings.

Common types of thermoplastic powder paint used for coating include polyethylene, polypropylene, nylon, and PVC. Each type of powder has its unique properties and is suitable for different applications, depending on the specific requirements of the substrate being coated.

Buy PECOAT® PE Thermoplastic Polyethylene Powder Paint

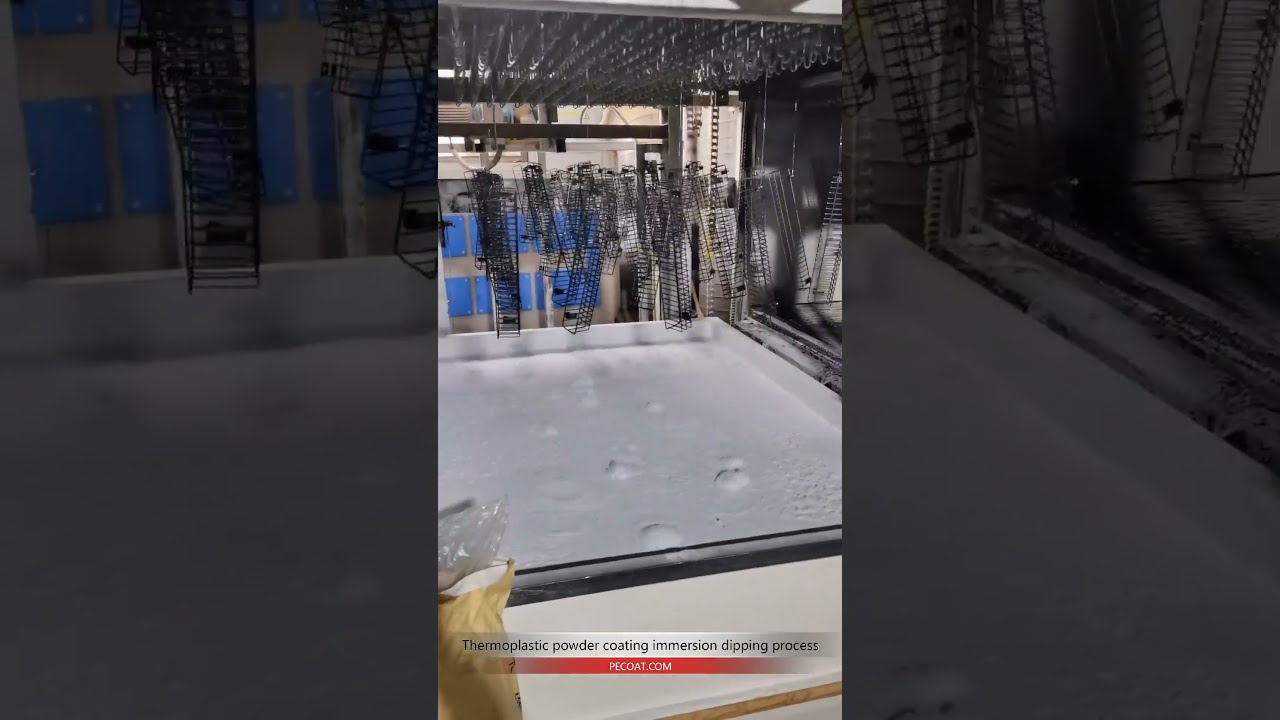

Fluidized Bed Dipping Process

What is The Use of PVC Powder?

PVC (Polyvinyl Chloride) powder is a versatile material that can be used in a wide range of applications due to its unique properties. It is a thermoplastic material that is made from a combination of vinyl chloride monomer and additives such as plasticizers and stabilizers. PVC powder is widely used in industries such as construction, automotive, medical, and packaging due to its durability, strength, and affordability. In construction, PVC powder is used for making pipes, fittings, and profiles. PVC pipesRead More …

Dip Powder Coating And Spray Powder Coating

1. Different concepts 1) Spray Powder coating: Spray Powder coating is a surface treatment method that involves spraying powder onto a product. The powder usually refers to thermosetting powder coating. The surface of powder-coated products is harder and smoother than that of dip-coated products. Electrostatic generators are used to charge the powder, which is then attracted to the surface of the metal plate. After baking at 180-220℃, the powder melts and adheres to the metal surface. Powder-coated products are oftenRead More …

Is Polyethylene Powder Coating Toxic ?

Polyethylene powder coating is a popular finish for metal surfaces due to its durability, flexibility, and resistance to chemicals and moisture. However, there is some concern about whether polyethylene powder coating is toxic and whether it poses any risks to human health and the environment. Polyethylene is a type of plastic that is used in a wide range of applications, including packaging, construction, and healthcare. It is generally considered to be a safe material, as it is non-toxic and doesRead More …

Polypropylene vs Polyethylene

Polypropylene (PP) and polyethylene (PE) are two of the most commonly used thermoplastic materials in the world. While they share many similarities, they also have distinct differences that make each material better suited for certain applications. Now let’s the commons and differences about polypropylene vs polyethylene Polypropylene is a versatile material that is used in a variety of industries, including automotive, packaging, and construction. It has a high melting point, which makes it resistant to heat and chemicals. It isRead More …

Relationship Between Mesh and Microns

Powder industry personnel often use the term “mesh size” to describe particle size. So, what is mesh size and how is it related to microns? Mesh size refers to the number of holes in a sieve, which is the number of holes per square inch. The higher the mesh size, the smaller the hole size. Generally, mesh size multiplied by hole size (in microns) ≈ 15000. For example, a 400-mesh sieve has a hole size of about 38 microns, andRead More …

How Fluidized Bed Powder Coating Works?

Fluidized bed powder coating is a process of coating a substrate with a fine powder material. The process involves suspending the powder material in a stream of air, creating a fluidized bed of powder that allows for even coating of the substrate. In this article, we will explore how fluidized bed powder coating works. The process of fluidized bed powder coating can be broken down into five main steps: substrate preparation, powder application, preheating, melting and curing. Step 1: SubstrateRead More …

Features and types of thermoplastic polymer

A thermoplastic polymer is a type of polymer that is characterized by its ability to be melted and then solidified repeatedly without any significant change in its chemical properties or performance characteristics. Thermoplastic polymers are widely used in a variety of applications, including packaging, automotive parts, electrical components, and medical devices, among others. Thermoplastic polymers are distinguished from other types of polymers, such as thermosetting polymers and elastomers, by their ability to be melted and reformed multiple times. This isRead More …

PVC coating for metal product is widely used

PVC coating for metal is a process where a layer of PVC (polyvinyl chloride) is applied onto a metal surface to provide protection against corrosion, abrasion, and other types of damage. This process is commonly used in various industries, such as construction, automotive, and manufacturing. The PVC coatings process involves several steps. First, the metal surface is cleaned to remove any dirt, oil, or other contaminants that may interfere with the adhesion of the coating. Next, the metal is typicallyRead More …

PVC Powder Coating Suppliers In China

General Steps to find PVC Powder Coating Suppliers from China I do not have access to real-time information or specific recommendations for suppliers of PVC powder coating. However, I can suggest a few ways you can find PVC powder coating supplier: Online search: You can use search engines like Google to search for PVC powder coating supplier. Try using relevant keywords like “PVC powder coating supplier” or “PVC powder coating manufacturers” to get a list of suppliers. You can alsoRead More …

Thermoplastic dip coating for complex-shaped parts

What is thermoplastic dip coating? Thermoplastic dip coating is a process where a heated thermoplastic material is melted and then applied to a substrate through dipping. The substrate, which is usually made of metal, is preheated to a specific temperature and then dipped into a container of molten thermoplastic material. The substrate is then withdrawn and allowed to cool, which causes the thermoplastic material to solidify and adhere to the surface of the substrate. This process is commonly used forRead More …