Category: Thermoplastic Powder Paint

Thermoplastic powder paint is a type of coating process that involves applying a dry powder paints of thermoplastic material onto a substrate, usually a metal surface. The powder is heated until it melts and forms a continuous, protective coating. This coating process can be done using several techniques, including electrostatic spraying and fluidized bed dipping.

Thermoplastic powder paints offers several advantages over traditional liquid coatings, including:

- Durability: Thermoplastic paints are highly durable and resistant to impact, abrasion, and chemicals, making them ideal for use in harsh environments.

- Ease of application: Thermoplastic powder paints can be applied more easily and uniformly than liquid coatings, which can help to reduce material waste and improve efficiency.

- Cost-effectiveness: Because thermoplastic paints can be applied more efficiently, they can often be less expensive than liquid coatings in the long run.

- Environmental friendliness: Thermoplastic paints are free of volatile organic compounds (VOCs), which can make them a more environmentally friendly alternative to liquid coatings.

Common types of thermoplastic powder paint used for coating include polyethylene, polypropylene, nylon, and PVC. Each type of powder has its unique properties and is suitable for different applications, depending on the specific requirements of the substrate being coated.

Buy PECOAT® PE Thermoplastic Polyethylene Powder Paint

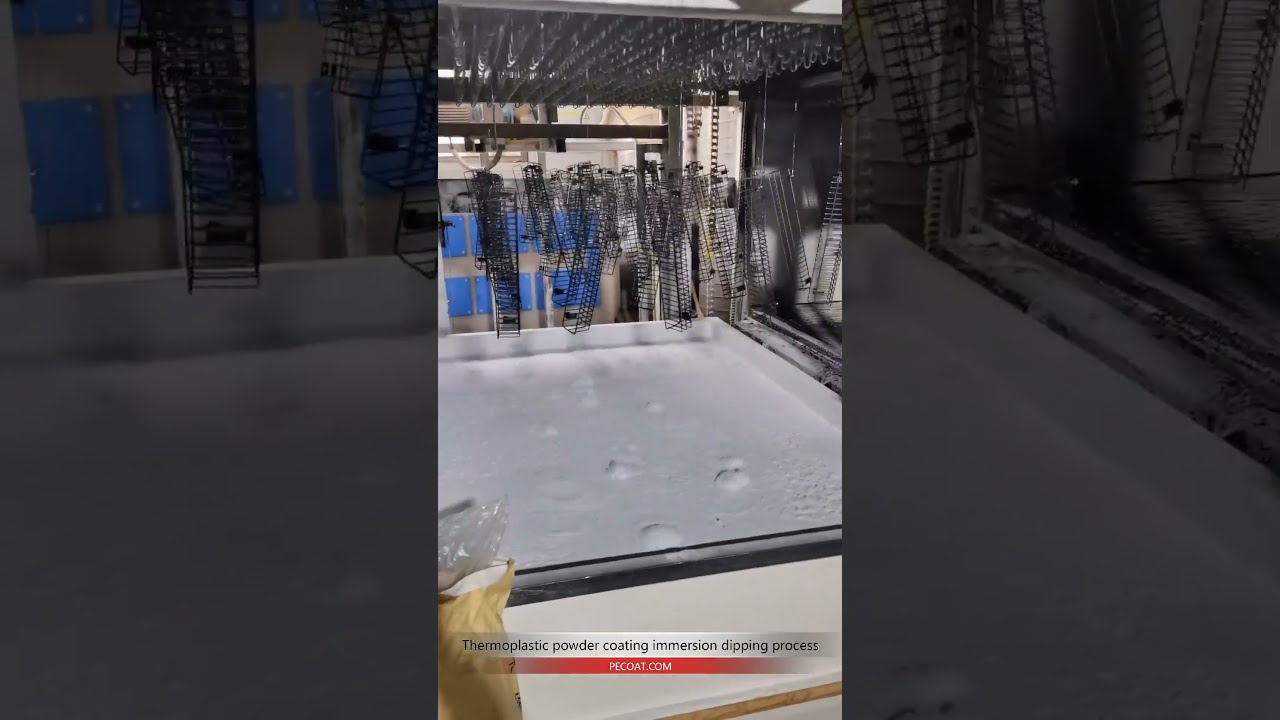

Fluidized Bed Dipping Process

Is PVC Thermoplastic?

PVC (polyvinyl chloride) is a thermoplastic material. Thermoplastics are a type of polymer that can be melted and re-molded multiple times without undergoing any significant chemical change. PVC is a thermoplastic polymer that is widely used in various applications due to its unique properties such as durability, flexibility, and resistance to chemicals and weathering. PVC is produced by polymerizing vinyl chloride monomer (VCM) through a process called suspension polymerization. The resulting polymer is a white powder that can be processedRead More …

Thermoplastic Materials In Different Types

Introduction Thermoplastic materials are a type of polymer that can be melted and re-molded multiple times without undergoing any significant chemical change. They are widely used in various industries due to their unique properties and versatility. One of the most significant advantages of thermoplastic materials is their ability to be molded into complex shapes with ease. This makes them ideal for use in manufacturing processes where intricate designs are required. Additionally, thermoplastics are lightweight and have excellent resistance to impact, makingRead More …

How to Hang Workpiece Properly in Thermoplastic Coating Dip Process?

Some of the suggestions below may not be the best, but you can try using them. If you have a better method, feel free to share it with us. When there are no hang holes or any place on the surface to hang the workpiece, how can we hang it better? Method 1: Use a very thin wire to bind the workpiece. After the dip coating process is completed and the coating is cooled, simply pull out or cut off the wire. Method 2:Read More …

Polyethylene Resin – Material Encyclopedia

What is polyethylene resin Polyethylene resin is a high polymer compound formed by the polymerization of ethylene molecules. It is also one of the most widely used plastics in the world. It has the characteristics of low density, high strength, corrosion resistance, high temperature resistance, not easy to aging, easy processing, etc. It is widely used in packaging, construction, home, medical, electronics and other fields. The price of polyethylene resin According to the monitoring data of the industrial product market,Read More …

Thermoplastic Powder Paint – Supplier,Develope,Pros and Cons

Supplier China PECOAT® specialized in production and export of thermoplastic powder paint, the product has polyethylene powder paint, pvc powder paint, nylon powder paint, and fluidized bed dipping equipment. Development History of Thermoplastic Powder Paint Since the oil crisis in the 1970s, powder coatings have rapidly developed due to their resource conservation, environmental friendliness, and suitability for automated production. Thermoplastic powder paint ( also called thermoplastic powder coating), one of the two main types of powder paint, started to emerge in theRead More …

What Is Thermoplastic Powder Coating Process

Thermoplastic powder coating is a process that involves the application of a thermoplastic polymer in a powder form onto a substrate. The powder is heated until it melts and flows onto the substrate, forming a continuous coating. This process is commonly used for coating metal surfaces, and offers advantages such as high durability, chemical resistance, and ease of application. The thermoplastic powder coating process begins with the preparation of the substrate. The substrate is cleaned and pre-treated to ensure thatRead More …

Nylon Coating On Metal

Nylon coating on metal is a process that involves applying a layer of nylon material onto a metal surface. This process is commonly used in various industries, including automotive, aerospace, and construction, to improve the durability, corrosion resistance, and aesthetic appeal of metal parts. The process of nylon coating on metal typically involves several steps. First, the metal surface is cleaned and prepared to ensure that it is free of any contaminants that may interfere with the adhesion of theRead More …

Is Thermoplastic Polymers Toxic?

Thermoplastic polymers are a type of plastic that can be melted and reshaped multiple times without undergoing any significant chemical changes. They are widely used in various industries, including packaging, automotive, construction, and medical. However, there is a growing concern about the potential toxicity of thermoplastic polymers and their impact on human health and the environment. The toxicity of thermoplastic polymers depends on several factors, including their chemical composition, additives, and processing methods. Some thermoplastic polymers, such as polyvinyl chlorideRead More …

What is fluidized bed?

A fluidized bed is a process that involves suspending solid particles in a fluid-like state, usually by blowing air or gas through the bottom of a container. This creates a bed of particles that are in constant motion and have the properties of both a liquid and a gas. Fluidized beds are commonly used in industrial processes such as chemical production, oil refining, and power generation. The concept of fluidization was first discovered in the 1930s by a British engineerRead More …

Nylon Powder Electrostatic Spray Coating Process

The electrostatic spray method utilizes the induction effect of a high-voltage electric field or the friction charging effect to induce opposite charges on the nylon powder and the coated object, respectively. The charged powder coating is attracted to the oppositely charged coated object, and after melting and leveling, a nylon coating is obtained. If the coating thickness requirement does not exceed 200 microns and the substrate is non-cast iron or porous, no heating is required for cold spraying. For powderRead More …