Polyethylene Powder Coating for Power Cable Conduit Pipe

Power cable conduit is a new type of composite material with a steel pipe as its base, which is coated on the inner wall with polyethylene powder coating or other coatings through a special process and cured at high temperature. Due to its good anti-static and anti-external signal interference capabilities, it is applied in cable burial and installation projects in various environments.

PECOAT® Polyethylene Powder Coating for Power Cable Conduit Pipe

PECOAT® PP506 is a polyethylene powder coating designed for coating power cable conduit pipe. It is a solvent-free, 100% solid powder coating developed with high-performance polyethylene as the base resin and combined with various specialty resins. This product has excellent adhesion, aging resistance, weather resistance, and good flowability. It is solvent-free, non-polluting, environmentally friendly, and energy-saving.

Property

| Items | Testing method | Unit | Test result |

| Density | GB/T 1033 | g/cm3 | 0.92 |

| Melt index | GB/T 3682 | g/10min | 12 |

| Tensile strength | GB/T 1040.2 | MPa | 10 |

| Elongation at break | GB/T1040.2 | % | 320 |

| Brittle temperature | GB/T5470 | ℃ | -70 |

| Ash content | GB/T8328 | % | 0.06 |

| Vicat softening point | GB/T1633 | ℃ | 92 |

| Bonding strength | CJ/T 225-2006 | N/cm | 110 |

Storage Method

Each bag of this product has a net weight of 25KG. It should be stored in a strictly waterproof, fireproof, moisture-proof, and sun-proof manner. Please properly seal and store any unused portion of the product. Note: This product is in powder form, so handle it with care during transportation to avoid the risk of dust explosion.

Instructions for Use of Power Cable Conduit Pipe Polyethylene Powder

This product is designed to be used as a coating material on power cable conduit steel pipes. It is applied to the surface of the pipes through processes such as dip coating or spray coating, where the polyethylene powder is melted and applied as a plastic layer. (Note: The surface temperature of the steel pipes during processing should be between 220-250℃.)

Base Pipe

When using welded steel pipes as the base pipe, it should comply with the provisions of GB/T 3091. When using spiral submerged arc welded steel pipes as the base pipe, it should comply with the provisions of SY/T 5037. When using seamless steel pipes as the base pipe, it should comply with the provisions of GB/T 8163.

Base Pipe Processing and Surface Treatment

- For straight seam welded steel pipes, the internal burrs should be cleaned, and the residual height of internal weld reinforcement should not exceed 0.5 mm.

- For coated steel pipes with grooves on both ends, the grooves on the base pipe should be processed before coating. No further groove processing should be done after coating. The groove processing should comply with the provisions of CJ/T 156.

- For coated steel pipes with socket and spigot on both ends, the socket and spigot should be processed on the base pipe before coating, and their dimensions should comply with the provisions of GB/T 13295.

- Before coating, the base pipe should be treated with processes such as sandblasting or acid pickling and phosphating to remove rust, oil stains, or oxide films on the surface of galvanized layers. For base pipes with DN>150, the rust removal grade should meet the requirements of Sa2.5 level specified in GB/T 8923.1-2009. The anchor pattern depth on the surface of the base pipe after treatment should be 40 μm to 100 μm.

- It is recommended to keep a distance of ten centimeters between the uncured sulfur bed and the steel pipe, which can be adjusted as needed.

Appearance Requirements

- The inner and outer walls of the coated steel pipe should be smooth and even in color, without defects such as scratches, pinholes, or foreign substances.

- For coated steel pipes with DN≤150, they should be straight for practical use or have bending requirements specified by mutual agreement between the supplier and the buyer. The bending curvature of coated steel pipes with DN>150 should not exceed 0.2% of the total length of the pipe, and both end faces should be perpendicular to the pipe axis.

- For coated steel pipes used for welding connections, the inner and outer coatings at the pipe ends should be removed, and a length of 100 mm to 150 mm should be reserved at the pipe ends.

- The color of the coating on the coated steel pipe can be determined through mutual agreement between the supplier and the buyer.

Project Case of Power Cable Conduit Pipe Polyethylene Powder

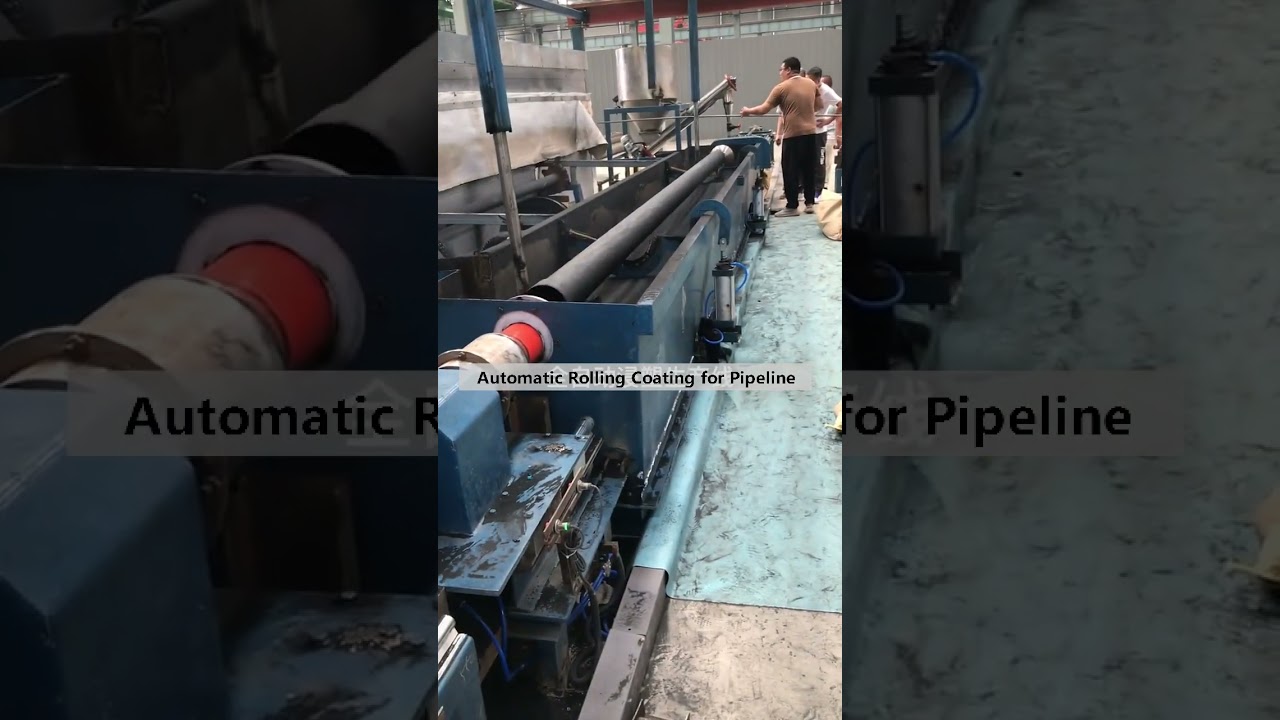

Coating Method

We are looking for pipe coating for water pipe,is this suitable?

do you have 3LPE coating